Volkswagen Polo Service & Repair Manual: Wire Break with Dual Repair Point

| Repair point with intermediate wire section |

| – |

Free up wire intended for repair at two points

(approximately 20 cm to both sides of respective repair points). |

| – |

If required, remove wiring harness wrapping using a folding

knife. |

|

|

|

| – |

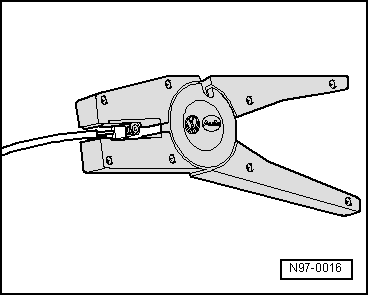

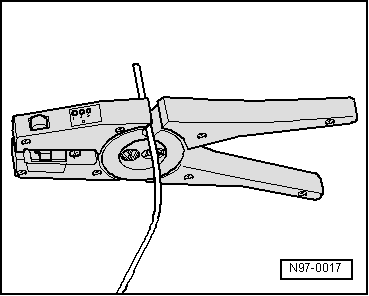

Route the yellow repair wire next to the damaged wiring

harness and cut the repair wire to the required length using the

Wiring Harness Repair Set - Wire Strippers -VAS1978/3-. |

| – |

Cut damaged wire section from the vehicle-specific single

wire. |

|

|

|

| – |

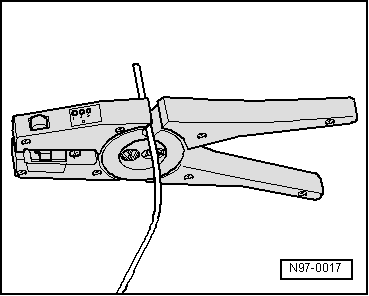

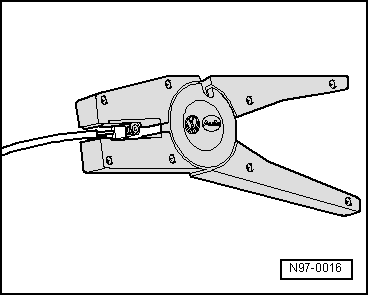

Strip the wire ends using the 6 - 7 mm wire stripper. |

| – |

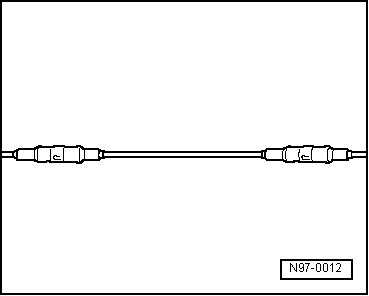

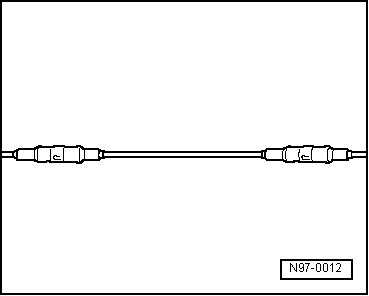

Slide crimp connection onto vehicle-specific single wire at

one side and onto repair wire at the other side. |

|

|

|

| – |

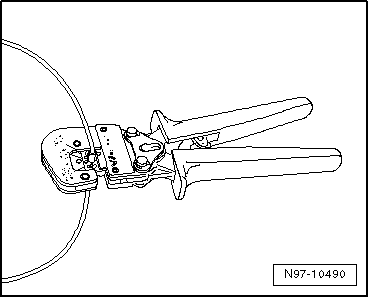

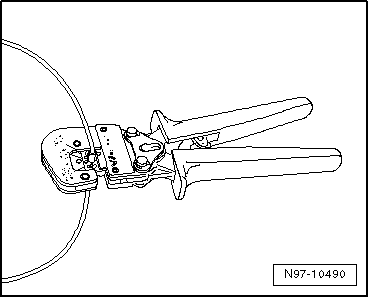

Crimp the crimp connection at both wire ends using crimp

pliers. |

| – |

Repeat this procedure at the other repair wire end. |

Note Note

| Always be sure to use the correct crimping slot for the

crimping connection used. Refer to

→ Chapter „Crimping Pliers with Insert“. |

| Do not crimp wire insulation. |

| After crimping, crimp connections must be heat-shrunk using

hot air gun to prevent moisture penetration. |

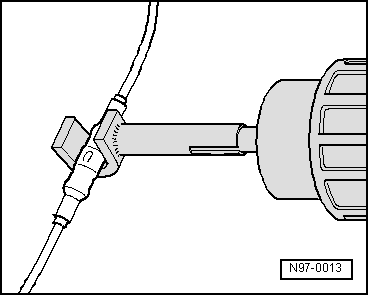

| – |

Place the Wiring Harness Repair - Blower - Shrink Element

-VAS1978/15A- on the Wiring Harness Repair Set - Hot Air Blower

-VAS1978/14A-. |

|

|

|

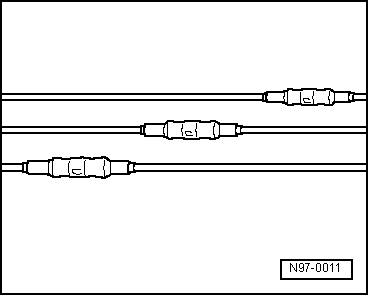

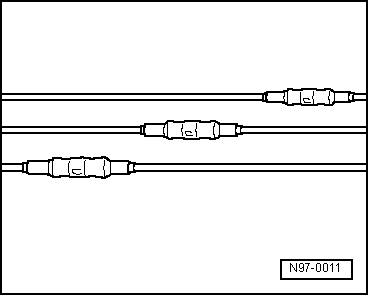

| Make sure that crimp connections do not lie directly next to

each other when several wires need to be repaired. Arrange the

crimp connectors at a slight offset so that the circumference of

the wiring harness does not become too large. |

| In the event the repair point was previous taped, this point

must be taped anew with yellow insulating tape after repairs. |

| Secure the repaired wiring harness if necessary with a cable

tie to prevent flapping noises while driving. |

|

|

|

Repair point with single crimp connection

–

Free up wire intended for repair (approximately 20 cm to

both sides of repair point).

...

Other materials:

Handbrake

Fig. 115 Handbrake between the front seats

First read and observe the introductory information

and safety warnings Applying the handbrake

Lift the handbrake lever up fully.

The handbrake is applied when the indicator lamp

lights up in the instrument cluster

.

Releasing ...

Checklist

To ensure your own safety and that of your passengers, observe

the following actions in the specified order :

Stop the vehicle at a safe distance

away from moving traffic and on a suitable surface .

Switch on the hazard warning lights

using the button .

Apply the handbrake ...

Overview - Tire Pressure Monitoring Sensor with Valve

1 -

Tire Pressure Monitoring Sensor

Supplied complete as a service part

Removing and Installing. Refer to

→ Chapter „Tire Pressure Monitoring Sensor with Valve, Removing and

Installing“.

When battery ...

© 2016-2026 Copyright www.vwpolo.net

Note

Note Note

Note Wire Break with Single Repair Point

Wire Break with Single Repair Point

Caution

Caution