Volkswagen Polo Service & Repair Manual: Two-Part HS Performance Filler

| Two-Part HS Performance Filler -LVM 014 100 A4-, white |

| Two-Part HS Performance Filler -LVM 014 173 A4-, dark gray |

| Two-Part HS Performance Filler -LVM 014 190 A4-, anthracite |

| These two-part performance fillers are high-quality two-part

HS acrylic-resin-based fillers. |

| Very good spray mist characteristics |

| Great stability under load |

| High solid content provides a high yield |

| Sheet steel that has been cleaned, sanded and primed with

Two-Part Wash Primer -LHV 043 000 A2- or One-Part Wash Primer -LVM

044 007/171 A2-, galvanized/electrolytically zinced sheet steel

or soft aluminum |

| Fine or non-sanded, thoroughly cleaned, original factory

primer. |

| Sanded factory paint or old paint (except TPA) |

| Surfaces prepared with two-part polyester products and then

sanded very fine. |

| Cleaned and sanded UP-GF surfaces, free of separating agents |

|

|

|

| Pre-treatment of base surfaces: |

| – |

Carefully clean using Silicone Remover -LVM 020 000 A5- or

Silicone Remover, Long -LVM 020 100 A5-. |

|

|

|

| – |

Use a suitable cleaning agent before reworking to ensure a

clean and residue-free surface. |

Note Note

| Stirring the Two-Part HS Performance Filler -LVM 014 ...- in

the mixer is recommended. |

|

|

|

| Two-Part VHS Performance Hardener -LVM 009 038 A2- |

| Two-Part VHS Performance Hardener, Long -LVM 009 039 A2- |

| (for very high technological resistance) |

Note Note

| Measuring by weight is possible with the Wizard Plus. |

| Please observe the country-specific explosion protection

regulations. |

| For Elastification. Refer to

→ Anchor. |

|

|

|

| Processing time/pot life: |

| – |

Ready to spray 45 to 75 minutes at +20 °C (68 °F) (depending

on the hardener and thinner used) |

| Two-Part Thinner -LVE 009 001 A5- |

| Two-Part Thinner, Long -LVM 009 300 A2- |

| Two-Part Thinner, Plus -LHA 014 000 A5- |

| Two-Part Thinner, Special -LVM 009 200 A2/A5- |

|

|

|

| – |

Processing viscosity 4 mm for +20 °C (68 °F) German Industry

Standardization 53211 |

| Processing viscosity 4 mm gravity feed spraygun “Compliant”

and “HVLP” is the mixed viscosity. |

|

|

|

| Adding 10 to 15 % VHS performance hardener at +20 °C (68 °F)

material temperature. |

| – |

Use a measuring stick to mix when pouring in the hardener. |

|

|

|

| – |

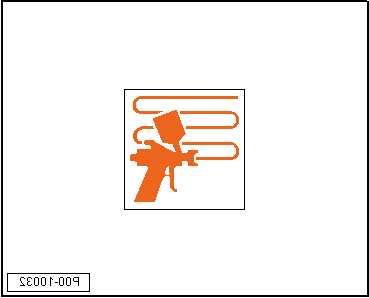

Set spray nozzle (see manufacturer's information):

“Compliant” 1.4 to 1.8 mm. |

| – |

Set spray nozzle (see manufacturer's information): “HVLP”

1.7 to 1.9 mm. |

| – |

Set spray pressure (see manufacturer's information):

“Compliant” to 1.5 to 2.0 bar. |

| – |

Set atomizing pressure (see manufacturer's information):

“HVLP” 0.7 bar. |

|

|

|

| – |

One to three spray applications (with intermediate drying

time) are required to get the recommended dry layer thickness of

between 60 and 250 µm. |

|

|

|

| The material can be sanded after 2 to 3 hours (layer

thickness of 60 to 150 µm after air drying at +20 °C (68 °F)

room temperature). |

| If the applied layer thickness is between 150 and 250 µm,

the material should be allowed to dry over night and then

sanded. |

|

|

|

| Final drying time with forced drying is a minimum of 5 to 15

minutes. |

|

|

|

| Forced drying at +60 °C (140 °F) object temperature for 15

to 20 minutes for a layer thickness of between 60 and 150 µm; 20

to 25 minutes for a layer thickness of between 150 and 250 µm |

|

|

|

| Final drying time for IR drying is a minimum of 5 to 10

minutes. |

|

|

|

| When IR drying (depending on layer thickness), use the

short-wave radiator for 10 minutes (of these, dry for 2 minutes

at 50 % power and 8 minutes at 100 % power) |

|

|

|

| – |

Dry-sand with rotary sander and dust extraction. P500-600

grit sandpaper |

|

|

|

| – |

Wet-sand with P800-1000 grit sandpaper |

|

|

|

| Can be painted over with: |

| Water-based base paint and two-part HS clear coat |

|

|

|

| Elastification for rigid and semi-rigid plastics: |

| The base material must first be mixed with 15 % Elastic

Additive -ALZ 011 001-. 4:1 mixing ratio for VHS performance

hardeners and 10 % thinner. |

| Any faults in the base surface can be filled with two-part

polyester filling paste. After drying and intermediate sanding,

insulate the filler patches with two-part VHS performance

filler. |

| The best insulating effect, even with critical surfaces, is

achieved with a medium layer of 80 to 120 µm in 2 spray passes,

with air-drying overnight, or oven or IR drying. With critical

surfaces, fine preparation is required and the parts must be

evenly filled. |

| The Two-Part HS Vario Filler -LGF 786 004 A4- (gray) is

recommended for insulating thermoplastic coatings. |

| When air drying, a minimum of +15 °C (59 °F) is recommended. |

|

|

|

| Personal Protective Equipment: |

| Note the safety data sheets |

| Wear the personal protective equipment during application |

|

|

|

| Delivery Viscosity |

Thixotropic |

| Flashpoint: |

above 23 °C (73.4 °F) |

| VOC value: 2004/42/IIB(c)(540)540 |

The EU limit for this product

(product category IIB.b) in ready-to-use form is a maximum of 540 g/L

volatile organic compounds. The VOC value of this product in

ready-to-use form is a maximum of 540 g/L. |

| The guaranteed shelf life is: |

| 24 months from date of manufacture for Two-Part HS

Performance Filler -LVM 014 ...-. |

| 12 months from date of manufacture for Two-Part VHS

Performance Hardener -LVM 009 038 A2-. |

| 36 months from date of manufacture for Two-Part VHS

Performance Hardener, Long -LVM 009 039 A2-. |

| Use no later than the date indicated on the label and store

in original container at +20 °C (68 °F). |

|

|

|

Definition:

Two-Part HS Mixed Filler -LGF 810 150 A4-, white

Two-Part HS Mixed Filler -LGF 810 151 A4-, black

...

Definition:

Two-Part Synthetic Adhesion Filler -LKF 696 009 A2-, white

Two-Part Synthetic Adhesion Filler -LKF 696 040 A ...

Other materials:

Severely Discharged Batteries, Charging with Battery Charger -VAS5900

Special tools and workshop equipment

required

Battery Charger -VAS5900-

WARNING

Risk of injury. Follow all Warnings and Safety

Precautions. Refer to

→ ...

Fender Corrosion Repair Measures, in Wheel Housing Liner Contact Area

Note

The corrosion protection in the fender seam must be applied on all

replacement parts, on which the attached seal is not already present.

The additional corrosion protection seal will prevent “chafe marks”

in the fender wheel housing liner.

...

After changing a wheel

First read and observe the introductory

information and safety warnings

Clean the tools as necessary and place them back in the toolbox in the

luggage compartment .

Stow the spare wheel, temporary spare wheel or the removed wheel safely

in the luggage compartment.

The tight ...

© 2016-2025 Copyright www.vwpolo.net

Note

Note Note

Note Two-Part HS Mixed Filler

Two-Part HS Mixed Filler Two-Part Synthetic Adhesion Filler

Two-Part Synthetic Adhesion Filler