Volkswagen Polo Service & Repair Manual: Refrigerant Circuit, Tracing Leaks, with Leak Detection System -VAS6196- or

Leak Detection Kit -VAS6201A- or Succeeding Model

Note Note

| This repair manual describes different methods for detecting

leaks in the refrigerant circuit. These methods have been tested

and result in success when used correctly. |

| If when searching for compressed air / Nitrogen or vacuum

leaks none are found, add a leak detection additive i.e UV leak

detection additive, to the electric leak detecting unit. |

| Minor leaks can be detected using an electronic leak

detector or UV leak detector lamp. |

| Many methods for detecting leaks in the refrigerant circuit

are offered in the open market. These methods do not always have

optimum results. If they are not used exactly according to

specifications, they can indicate refrigerant circuit components

have leaks even when they do not. Also, refrigerant circuit

components can be damaged by some methods. |

| Do not repair components with leaks. Replace them with new

original parts. |

| Do not charge a leaking refrigerant circuit with

refrigerant. Evacuate the circuit and check it for leaks before

charging. Refer to

→ Chapter „Refrigerant Circuit with A/C Service Station,

Draining“. |

Caution

Caution

| If it is suspected that chemicals were added to the

refrigerant circuit to seal leaks, do not connect the

A/C service station and do not extract the refrigerant. |

| Chemicals that seal leaks in the coolant circuit

form deposits that affect the function of the A/C system

and lead to failure of the A/C system and the A/C

service station. |

| Inform that customer that there are substances in

the A/C system that are no approved by Volkswagen. This

A/C system cannot be drained or serviced in the

workshop. |

|

Note Note

| VW does not approve the use of chemicals to seal leaks in

the refrigerant circuit. |

| Chemicals used to seal leaks in the refrigerant circuit

often react with air and the moisture in it. They cause deposits

in the refrigerant circuit and the A/C service station and

malfunctions in valves and other components that they come in

contact with. These deposits cannot be removed completely from

the components, even by flushing. |

| Chemicals used to seal leaks in the refrigerant circuit

usually cannot be detected from outside. The label that should

be applied to identify it is often missing. Therefore be careful

when working with if you do not know its service history. |

| Accessories offer containers used to separate out these

chemicals (used to seal leaks in the refrigerant circuit).

Because VW does not approve the use of these chemicals, there is

no evidence of the effectiveness of these filters. |

Note Note

| Small leaks can be detected using a UV-leak detection

additive for example. |

| – |

Discharge the refrigerant circuit with the A/C service

station. Refer to

→ Chapter „Refrigerant Circuit with A/C Service Station,

Draining“. |

Note Note

| Be ready to evacuate a large leak should one be found. Refer

to

→ Chapter „Refrigerant Circuit with A/C Service Station,

Draining“. |

| If no leak is found during evacuation or there is a leak

that is so small that the location cannot be found, proceed as

follows. Refer to

→ Chapter „Searching for Refrigerant Circuit Leaks with

Compressed Air or Nitrogen“. |

| Currents of air quickly disperse refrigerant gas. Draughts

must therefore be avoided during leak detection. |

| If the refrigerant circuit is completely empty, fill with

refrigerant to approximately 10% of the fill capacity (R134a

label or vehicle-specific Repair Manual). |

|

|

|

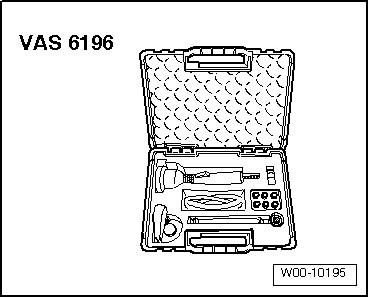

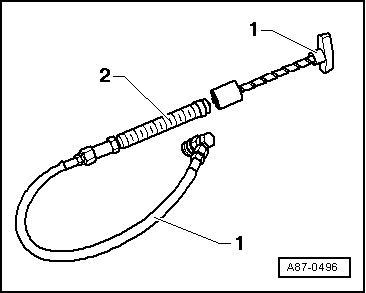

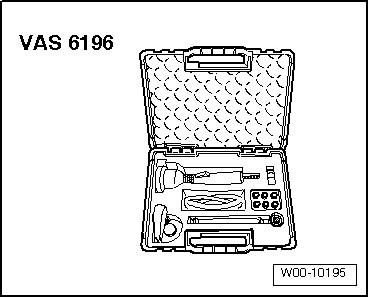

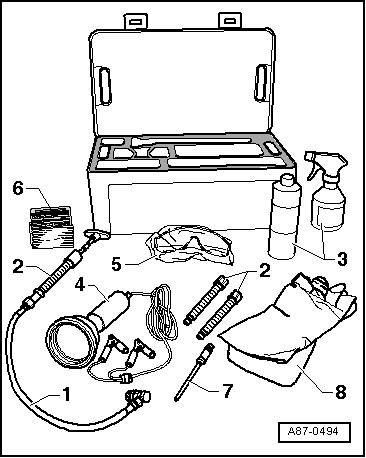

| Leak Detection System -VAS6196- |

|

|

|

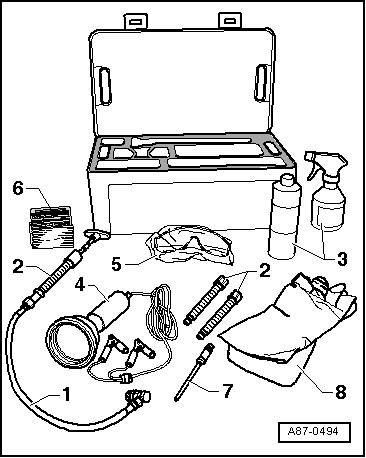

| Leak Detection System -VAS6201- or succeeding model |

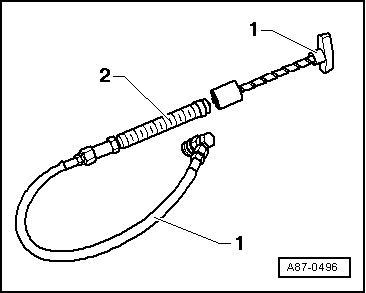

| 1 - |

Leak Detection Kit - Hand Pump w/Cartridge -VAS6201/1- |

| 2 - |

Leak Detection Kit - Cartridge -VAS6201/2- |

| 3 - |

Leak Detection Kit - Cleaning Solution -VAS6201/3- |

| 4 - |

UV Leak Detection Lamp -VAS6201/4A- |

| 5 - |

Leak Detection Kit - Eye Protection -VAS6201/6- |

| 6 - |

Leak Detection Kit - Label -VAS6201/7- |

| 8 - |

Leak Detection Kit - Hand Protection -VAS6201/9- |

|

|

|

| Filling with leak detection additive when the refrigerant

circuit is empty |

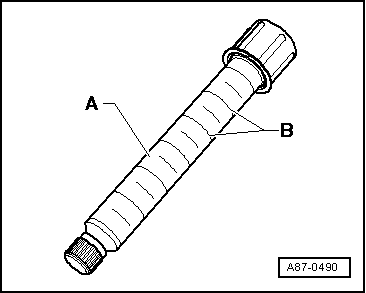

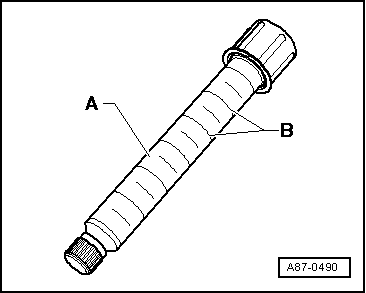

| The cartridge -A- contains 15.4

ml of leak detection additive (one unit

-B- corresponds to 2.5 ml). |

|

|

|

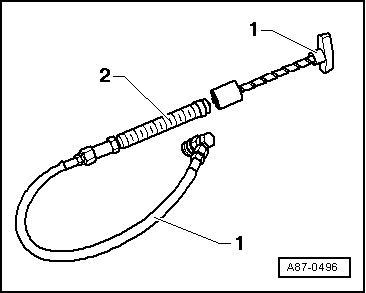

| – |

Assemble the Leak Detection Kit -VAS6201A--1-

with the cartridge -2-Leak

Detection Kit - Cartridge -VAS6201/2-. |

| – |

Insert the Leak Detection Kit - Filler Tube -VAS6201/8- into

the hand pump. Refer to

→ Anchor-7- |

| – |

Open the hand pump service valve. |

|

|

|

| Leak detection additive is best added to empty refrigerant

circuit via opened connection. |

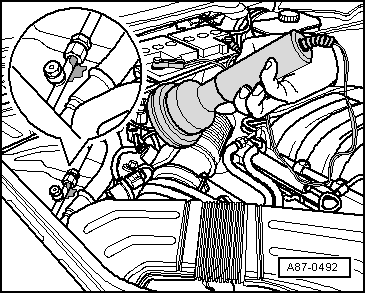

| – |

Open an easily accessible connection point on refrigerant

circuit |

| – |

Cover area around connection point with foil or absorbent

paper. |

| – |

Tighten the toggle on the hand pump until the leak detection

additive comes out of the tube. |

| – |

Add 2.5 ± 0.5 ml (milliliter = cm3)

of leak detection additive to the refrigerant circuit. |

Note Note

| If leak detection additive was already added to the

refrigerant circuit for an earlier repair, note the following:

Only add new leak detection additive if the refrigerant oil will

be replaced. If only a portion of the refrigerant oil was

replaced, only add a proportionate amount of the leak detection

additive. For example, if 100 ml of refrigerant oil was replaced

in a vehicle with 250 ml, add only 1 ml (cm3)

of leak detection additive. |

| – |

Replace the O-rings on opened connection point. |

| – |

Assemble refrigerant circuit |

| – |

Apply a label near the service connection stating that leak

detection additive was added to the refrigerant circuit. |

| – |

Evacuate and recharge refrigerant circuit according to

specification. Refer to

→ Chapter „Refrigerant Circuit with A/C Service Station,

Draining“ and

→ Chapter „Refrigerant Circuit with A/C Service Station,

Filling“. |

Note Note

| The A/C system must run for at least 60 minutes so the

additive distributes itself through the entire refrigerant

circuit. The compressor must be running. Depending on the size

of the leak, it may become visible within that time. |

| – |

Find the leak in the refrigerant circuit with the UV lamp

VAS6196/4. Refer to

→ Anchor. |

Note Note

| Remove existing leak detection additive in the engine

compartment or from the refrigerant circuit components using

Leak Detection Kit - Cleaning Solution -VAS6201/3-. |

| Leak detection additive with filled refrigerant circuit,

filling |

Note Note

| If leak detection additive was already added to the

refrigerant circuit for an earlier repair, note the following:

Only add new leak detection additive if the refrigerant oil will

be replaced. If only a portion of the refrigerant oil was

replaced, only add a proportionate amount of the leak detection

additive. For example, if 100 ml of refrigerant oil was replaced

in a vehicle with 250 ml, add only 1 ml (cm3)

of leak detection additive.

|

| A small quantity of leak detection additive remains in the

service connection. Carefully remove this residual amount so a

leaking area is not detected erroneously upon a later leak

detection. |

|

|

|

| The cartridge -A- contains 15.4

ml of leak detection additive (one unit

-B- corresponds to 2.5 ml). |

|

|

|

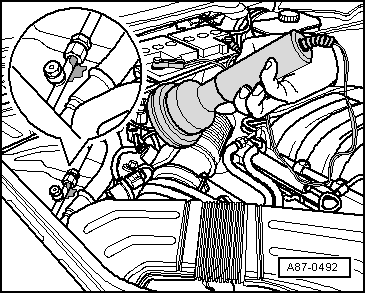

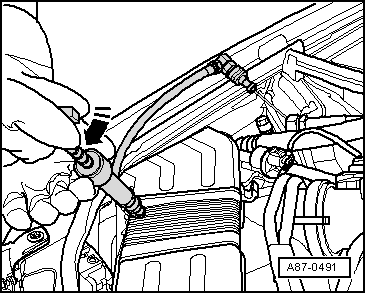

| – |

Remove sealing cap from service connection of low pressure

side in refrigerant circuit. |

| – |

Assemble the Leak Detection Kit -VAS6201A--1-

with the cartridge -2-Leak

Detection Kit - Cartridge -VAS6201/2-. |

Note Note

| Make sure the hand pump hose is completely filled with leak

detection additive. |

| – |

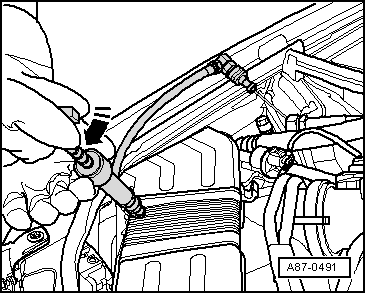

Place the quick-release coupling on the low pressure side

service connection and tighten the hand wheel to open the

service coupling. Hold the hose upward and tighten the handle of

the hand pump just enough until the leak detection additive

starts to emerge from the tube. |

|

|

|

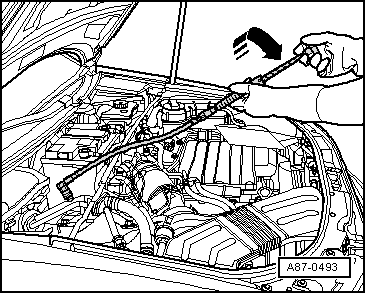

| – |

Cover area around service connection on vehicle with foil or

absorbent paper. |

| – |

Tighten the toggle on the hand pump to add 2.5 ± 0.5 ml

(milliliter = cm3) of leak detection

additive to the refrigerant circuit. |

|

|

|

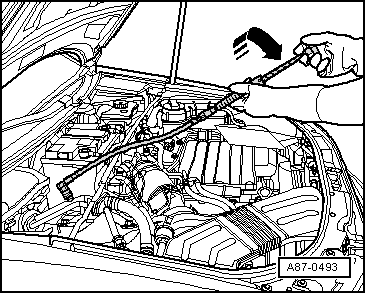

| – |

Move vehicle into a slightly darker area of the workshop

(with daylight or bright lighting the effect of the UV light is

diminished). |

| – |

Check the accessibility of the various components in the

refrigerant circuit and remove any components in the area that

block access to the refrigerant circuit such as noise insulation

and the bumper. |

| – |

Wear protective eyewear to protect the eyes. |

| – |

Connect the UV-lamp to a 12 volt battery (vehicle battery).

Observe the correct polarity of connections. |

| – |

Switch on the UV lamp and illuminate the components of

refrigerant circuit. Locations where refrigerant, refrigerant

oil and leak detection additive has leaked out light up under

fluorescent UV light. |

Note Note

| The leak detection additive can remain in the refrigerant

circuit. |

| Remove existing leak detection additive in the engine

compartment or from the refrigerant circuit components using

Leak Detection Kit - Cleaning Solution -VAS6201/3-. |

|

|

|

Note

This repair manual describes different methods for detecting

leaks in the refrigerant circuit. These methods have been tested

and result in ...

Other materials:

Various securing systems

Fig. 62 On the rear seats: figure Ⓐ illustrates

the main securing points for the child restraint system on the lower retaining rings

and top tether. Figure Ⓑ shows how to secure a child restraint system using the

vehicle's seat belt

First read and observe the introductory information

a ...

Technical requirements

First read and observe the introductory information

and safety warnings

If the vehicle is supplied with a factory-fitted towing bracket

it will already have the necessary technical modifications and meet the statutory

requirements for towing a trailer.

Only use a towing bracket that is appr ...

Two-Part HS Vario Clear Coat

Definition:

Two-Part HS Vario Clear Coat -L2K 769 K01 A5-

Edition 06/2013

Product Description

Two-part HS vario clear coat is a VOC compliant (VOC value

less than 420 g/L), h ...

© 2016-2025 Copyright www.vwpolo.net

Note

Note Note

Note Note

Note Note

Note Note

Note Note

Note Note

Note Note

Note Note

Note Note

Note Note

Note Note

Note Note

Note Refrigerant Circuit, Tracing Leaks, with Electronic Leak Detector -VAG1796

Refrigerant Circuit, Tracing Leaks, with Electronic Leak Detector -VAG1796

Caution

Caution

WARNING

WARNING