Volkswagen Polo Service & Repair Manual: Electrically Driven A/C Compressor, Flushing

| Vehicles with a high voltage system |

| Observe all of the additional warnings for all work

performed on vehicles with the high voltage system. Refer to

→ Electrical Equipment; Rep. Gr.93. |

WARNING

WARNING

| Risk of unintended engine start |

| The ignition must be turned off and the ignition key

must remain outside of the vehicle when working on

vehicles with a high voltage system. |

|

WARNING

WARNING

| Handling high voltage cables: |

| Do not stand on or place tools on high voltage

cables and their components as it may damage the cable

insulation. |

| Never bend or kink high voltage cables forcefully as

it may damage the cable insulation. |

| The round high voltage connectors are color coded

with an external color ring and are mechanically coded

using the guide- or code tabs. Always make certain that

the coding matches when connecting the round connector

in order to avoid any mechanical damage the high voltage

connector.

|

|

DANGER!

DANGER!

| There is a risk of electrocution from damaged high

voltage components. |

| Observe the following when working around high

voltage components and high voltage wires: |

| Never work around high voltage components and cables

with cutting, deformed, or sharp edged tools, or heat

sources such as welding or soldering tools, heated air,

and thermal glue. |

| Inspect the high voltage components visually before

beginning. |

| Perform a visual inspection of the Electric Drive

Power and Control Electronics -JX1-, the Electro-Drive

Drive Motor -V141-, the Electrical A/C Compressor -V470-

and the high voltage lines when working in the engine

compartment. |

| Perform a visual inspection of the high voltage

lines and covers when working on the underbody. |

| Perform a visual inspection of the high voltage

lines and the Electrobox with the High Voltage System

Maintenance Connector -TW- when working in the luggage

compartment. |

| Perform a visual inspection on all of the potential

equalization cables. |

| Observe the following items when performing the

visual inspection: |

| The components do not display any signs of external

damage.

|

| The high voltage cable insulation and the potential

equalization cables are not damaged. |

| The high voltage cables do not display any abnormal

deformations.

|

| Every high voltage component is marked with a red

warning label. |

|

| If it is necessary to perform work in the vicinity of high

voltage components, perform a “visual inspection” of the high

voltage components and cables for damage and follow the “general

warnings when working on the high voltage system”. Refer to

→ Electrical Equipment; Rep. Gr.93. |

| If it is necessary to perform work on the high voltage

components, disable the high voltage system. Refer to

→ Electrical Equipment; Rep. Gr.93 and read and

follow the “high voltage electrical system general warnings”

→ Electrical Equipment; Rep. Gr.93. |

Note Note

| The electrically driven A/C compressor is to be flushed

when, there is dirt, too much refrigerant oil is in the

refrigerant circuit, or is contaminated (with moisture debris)

and to remove refrigerant oil from the A/C compressor. In these

cases the refrigerant circuit must also be flushed, so that it

will be cleaned and the correct refrigerant oil quantity for the

refrigerant circuit can be set. |

| If an electrically-driven A/C compressor is being replaced

that does not have a mechanical fault (for example, a faulty

circuit board), then determine how much refrigerant is in this

A/C compressor. |

Note Note

| This A/C compressor must be flushed to get all the

refrigerant oil out.

|

| The A/C compressor is flushed in the flow direction (from

the low pressure side input to the high pressure side output) |

| So that as much refrigerant oil as possible is flushed out

of the A/C compressor, the A/C compressor must be positioned so

that the high pressure side output is as low as possible. |

| If an A/C service station without a flushing program is

used, the procedure must be performed manually (evacuate, flush

3 times with at least 2 kg refrigerant each and extract

refrigerant again, evacuate). |

| Quantity: for example 50 cm³ |

| Pour so much refrigerant oil out of the new A/C compressor

so that only the amount remains (plus 10 cm

3) that had been flushed out of the

old A/C compressor beforehand. If the new original A/C

compressor has for example, 200 cm3,

then only pour out 140 cm3. |

| – |

Pour old refrigerant oil out of A/C compressor. Handling

refrigerant oil. |

Note Note

| In not enough refrigerant oil can be poured out from the A/C

compressor to be installed, flush the new A/C compressor. After

flushing, fill the A/C compressor to be installed with as much

new refrigerant oil as was flushed from the replaced A/C

compressor. |

|

|

|

Note

Note

| Flushing the A/C compressor is performed manually. |

| – |

Extract the refrigerant, if necessary. |

| – |

Empty the Service Station old oil container. |

Note

Note

| On some Service Stations, the oil is first separated in the vacuum

phase and then it goes into the old oil container. |

| – |

Set the amount of refrigerant on the Service Station to 2 kg and the

oil quantity to 0. |

| – |

Set up the Refrigerant Circuit Flushing Device -VAS6336/1- or Air

Conditioning Flush Tool -VAS6337/1A- between the A/C service station and

refrigerant circuit return line. |

| – |

Evacuate the refrigerant circuit for 10 minutes. Then observe the

vacuum display. If the vacuum remains constant, then fill the circuit

with 2 kg refrigerant R134a. Then extract again and repeat the procedure

one more time. |

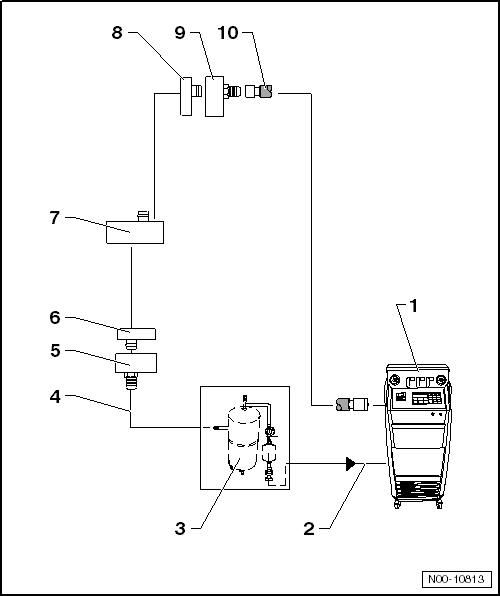

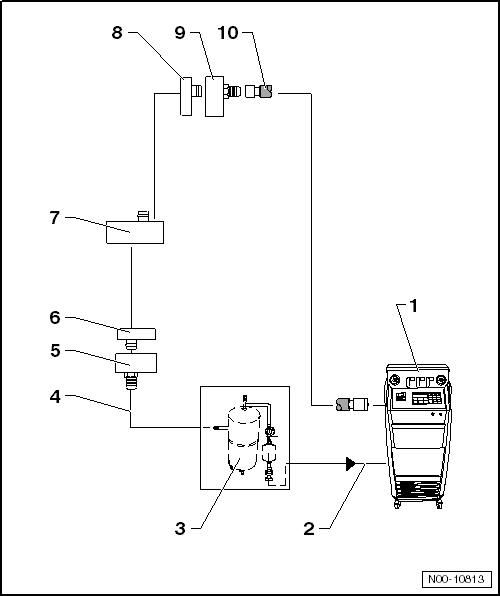

| 2 - |

A/C service station refrigerant hose |

| From the low pressure side of the service station (mostly blue) to

the output of the flushing device for refrigerant circuits. |

| 3 - |

Flushing equipment for refrigerant circuits |

| Different versions and different construction, for example

Refrigerant Circuit Flushing Device -VAS6336/1- or Air Conditioning

Flush Tool -VAS6337/1-. |

| With filter, viewing glass, security valve, heater, refrigerant

container, etc. (depending on version). |

| Depending on the construction of the A/C service station and of

refrigerant circuit flushing device, a check-valve may be installed at

output of refrigerant circuit flushing device (to guarantee correct

direction of refrigerant flow during flushing). |

| 4 - |

Charge hose for refrigerant circuit flushing device |

| From the high pressure side connection of the A/C compressor on the

refrigerant circuit (smaller diameter) to input of Refrigerant Circuit

Flushing Device -VAS6336/1- or Air Conditioning Flush Tool -VAS6337/1A-. |

| 5 - |

Adapter to connection for high pressure side on refrigerant circuit |

| The Refrigerant Circuits Adapter Set 1 - Adapter 3 -VAS6338/3- from

the Refrigerant Circuits Adapter Set 1 -VAS6338/1- |

Note

Note

| If the Refrigerant Circuits Adapter Set - Adapter 40 -VAS6338/40- is

available, the filler hose can be directly attached to the A/C

compressor.

|

| 6 - |

High pressure side refrigerant line from A/C compressor |

Note

Note

| Is not used if the Refrigerant Circuits Adapter Set - Adapter 40

-VAS6338/40- is available. |

| – |

Remove the centering pin from the refrigerant line so that the

Refrigerant Circuits Adapter Set 1 - Adapter 3 -VAS6338/3- fits. |

| 7 - |

Electrically-driven A/C compressor |

| The A/C compressor is flushed in the flow direction (from the low

pressure side input to the high pressure side output) |

| So that as much refrigerant oil as possible is flushed out of the

A/C compressor, the A/C compressor must be positioned so that the high

pressure side output is as low as possible. |

| 8 - |

Low pressure side refrigerant line to A/C compressor |

Note

Note

| Is not used if the Refrigerant Circuits Adapter Set - Adapter 41

-VAS6338/41- is available. |

| – |

Remove the centering pin from the refrigerant line so that the

Refrigerant Circuits Adapter Set 1 - Adapter 6 -VAS6338/6- fits. |

| 9 - |

Adapter for connecting low pressure side to refrigerant circuit |

| The Refrigerant Circuits Adapter Set 1 - Adapter 6 -VAS6338/6- from

the Refrigerant Circuits Adapter Set 1 -VAS6338/1- |

Note

Note

| If the Refrigerant Circuits Adapter Set - Adapter 41 -VAS6338/41- is

available, the filler hose can be directly attached to the A/C

compressor.

|

| 10 - |

A/C service station refrigerant hose |

| From the A/C service station high pressure side (mostly colored red)

to the connection on the low pressure line, or directly on the A/C

compressor with the Refrigerant Circuits Adapter Set - Adapter 41

-VAS6338/41-. |

Note

The arrows in the following illustrations show the direction

of refrigerant flow while flushing. During flushing, refrigerant

flows in the o ...

The following table lists the different adapters necessary

to connect the service station to the refrigerant circuit, to

flush and to bypass the removed receiver/drye ...

Other materials:

Receiver/Dryer

Caution

Non-approved tools or materials such as leak sealing

additives can cause damage or malfunctions in the

system.

Only use tools and materials approved by the

manufactu ...

Introduction

This chapter contains information on the following subjects:

→ General information on transporting children in the vehicle

→ Various securing systems

→ Using a child seat on the front passenger seat

→ Using a child seat on the rear seats

→ Securing c ...

Decorative Trims, Replacing, Bolted Decorative Trims

These disc wheels are equipped with replaceable decoration

elements. Note the following when installing.

–

Clean the thread in the disc wheel before screwing in the

new bolts.

...

© 2016-2026 Copyright www.vwpolo.net

Note

Note Note

Note Note

Note

Note

Note Note

Note Note

Note Note

Note Note

Note Note

Note Flushing Circuit Block Diagrams

Flushing Circuit Block Diagrams Adapter for Assembling Flushing Circuit

Adapter for Assembling Flushing Circuit

WARNING

WARNING