Volkswagen Polo Service & Repair Manual: Battery Terminal Clamp and Battery Terminal, Cleaning

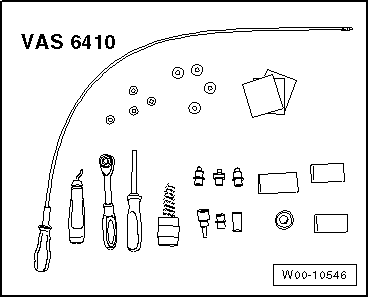

| Special tools and workshop equipment

required |

| Torque Wrench 1331 5-50Nm -VAG1331- |

| The Contact Surface Cleaning Set -VAS6410- makes optimal

repair quality possible in the realm of vehicle electronics.

Using the tools, service work can be performed in the area of

the contact sensor on the threaded connection wiring harnesses

in the high current circuit (starter and charging current). The

Contact Surface Cleaning Set -VAS6410- is adapted to the vehicle

structural measurements and ensures correct servicing and a

comfortable procedure. |

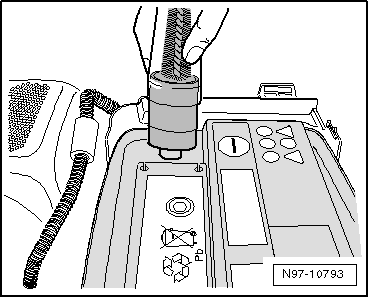

Note Note

| The illustrations of the service work only serve as

examples. |

|

|

|

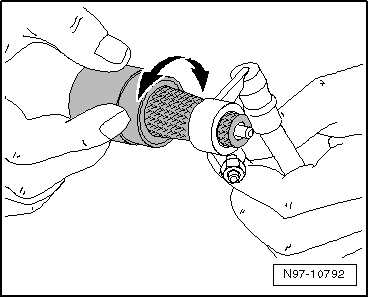

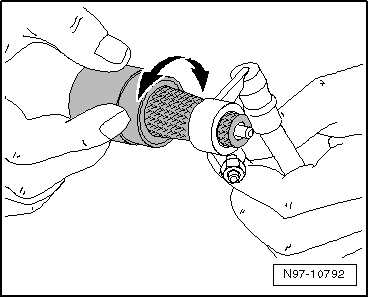

| – |

The battery terminal clamp is cleaned with the battery

terminal cleaner wire brush using circular motions. |

|

|

|

Special tools and workshop equipment

required

Torque Wrench 1331 5-50Nm -VAG1331-

Note

Do not use r ...

Caution

Missing protection leads to the electrical system

damage.

Note

...

Other materials:

Silicone Remover

Definition:

Silicone Remover -LSW 019 000 A5-, watery

Silicone Remover -LVM 020 000 A5-

Silicone Remover, Long -LVM 020 100 A5-

Edition 02/2012

S ...

Tires, Mounting, Run-Flat Tires and Ultra High Performance Tires

Only trained personnel can perform the assembly work on

run-flat tires and ultra high performance tires.

If equipped check the tire pressure monitoring sensor with

the vehicle diagnostic tester and if necessary replace.

...

Ignition lock

Fig. 107 Positions of the vehicle key in

the ignition lock

First read and observe the introductory information

and safety warnings The steering lock can be activated when

there is no vehicle key in the ignition lock.

Vehicle key positions

Ignition switched off. The vehicle key ca ...

© 2016-2025 Copyright www.vwpolo.net

Note

Note Note

Note Note

Note Threaded Connections, Repairing

Threaded Connections, Repairing Protecting

Protecting

WARNING

WARNING