Volkswagen Polo Service & Repair Manual: Two-Part Filler

| Two-Part Filler -LLS MAX 202 M2-, medium gray |

| The Two-Part Filler -LLS MAX 202 M2-, (medium gray) is a

high-quality two-part HS sanding filler. The raw material base

is acrylic resin. |

| Constant atomizing pressure |

| Optimal and stable processing properties |

| Great stability under load |

| Excellent high-build characteristics |

| Application area: clever repair |

| Professional painting result |

Note Note

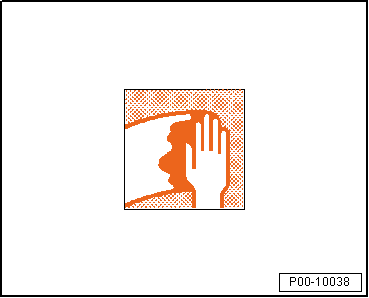

| For work safety, wear appropriate, personal protective

equipment. |

| Sheet steel that has been cleaned, sanded and primed with

Two-Part Wash Primer -LHV 043 000 A2- or One-Part Wash Primer -LVM

044 007 A2-/-LVM 044 171 A2-, galvanized/electrolytically zinced

sheet steel or soft aluminum. |

| Finely sanded, thoroughly cleaned, original factory primer. |

| Sanded factory paint or old paint (except TPA). |

| Surfaces prepared with two-part polyester products and then

sanded very fine. |

| Cleaned and sanded UP-GF base surfaces, free of separating

agents. |

|

|

|

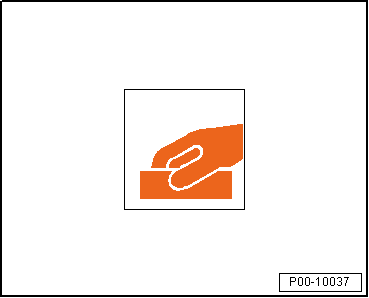

| Pre-treatment of base surfaces: |

| – |

Carefully clean using Silicone Remover -LVM 020 000 A5- or

Silicone Remover, Long -LVM 020 100 A5-. |

|

|

|

| – |

Sand the factory- or old paint. |

| – |

Thoroughly remove any potential rust spots and sand any

transitions to old paint. |

|

|

|

| – |

Use a suitable cleaning agent before reworking to ensure a

clean and residue-free surface. |

|

|

|

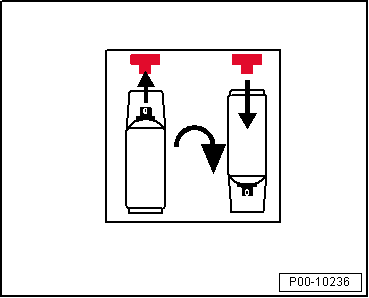

| Activating the Two-Part Spray Can: |

|

|

|

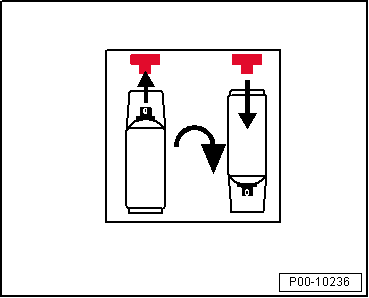

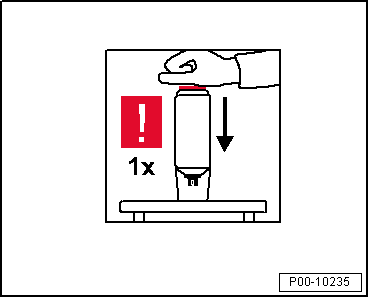

| – |

Remove the red push button on the cap and set it on the

valve for the hardener mixture on the bottom of the can. |

|

|

|

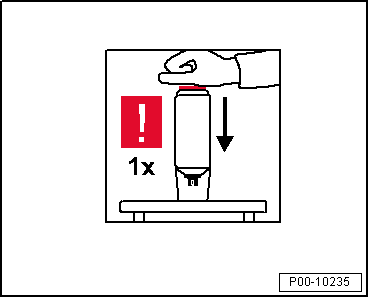

| – |

Press in the valve for the hardener mixture. Make sure when

pressing down the valve for the hardener mixture that the can is

upside down. |

|

|

|

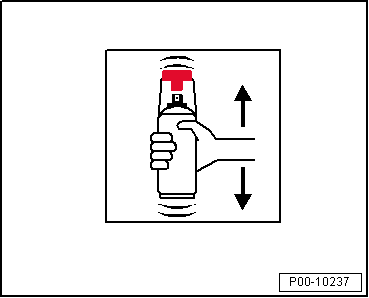

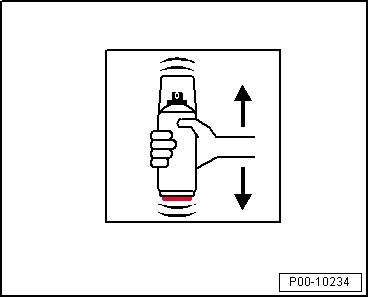

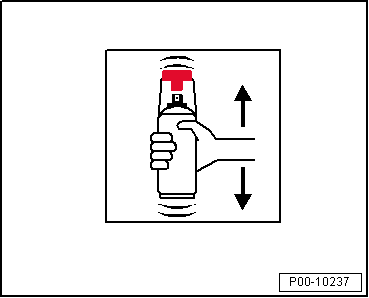

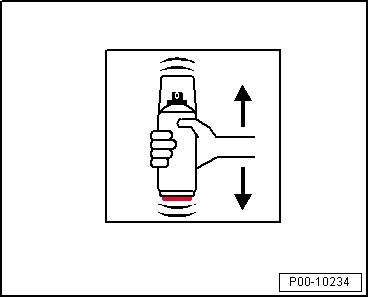

| – |

Shake the can thoroughly for two minutes. |

|

|

|

| Processing time/pot life: |

| – |

Eight hours at +20 °C (68 °F) |

|

|

|

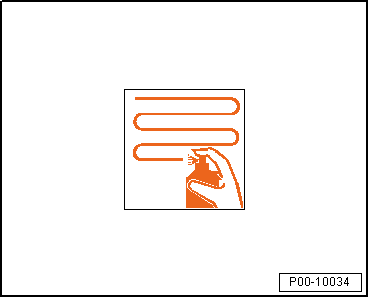

| – |

Apply two to three spray applications to cover with a 5 to

10 minute intermediate ventilation time. |

| – |

Maintain a distance of 20 to 25 cm. |

| – |

The recommended dry layer thickness is approximately 80 to

120 µm. |

Note Note

| If the spraying procedure is interrupted, make sure that the

valve above the spray head is empty to prevent any nozzle

blockage. |

|

|

|

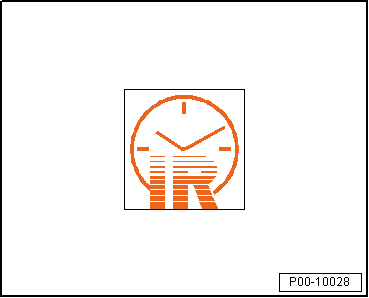

| Air drying at +20 °C (68 °F) room temperature is: |

| Three to four hours for a dry layer thickness of 80 to 120

µm. |

|

|

|

| The drying time with forced drying is at least 5 to 15

minutes. |

| Forced drying at +60 °C (140 °F) object temperature is 30 to

40 minutes for a layer thickness of 80 to 120 µm. |

|

|

|

| The drying time for IR drying is a minimum of 5 to 10

minutes. |

|

|

|

| IR drying for a layer thickness of 80 to 120 µm is 10

minutes with a short-wave heater and 15 minutes with a

medium-wave heater. |

|

|

|

| – |

Dry-sand with rotary sander and dust extraction. P400-500

grit sandpaper. |

|

|

|

| – |

Wet-sand with P800-1000 grit sandpaper |

|

|

|

| VOC value: 2004/42/IIB(e)(840)690 |

The EU limit for this product

(product category IIB.b) in ready-to-use form is a maximum of 840 g/L

volatile organic compounds. The VOC-value of this product in

ready-to-use form is a maximum of 690 g/L. |

| The guaranteed shelf life of 36 months from date of

manufacture. Use no later than the date indicated on the label

and store in original container at +20 °C (68 °F). |

|

|

|

One-Part Clean Spray Can -LLS MAX 112-, 400 ml for

Water-Based Mixed Paint “Aqua Premium System”

Edition 05/2014

Product D ...

Definition:

Two-Part Clear Coat -LLS MAX 210-

Edition 12/2010

Product Description

...

Other materials:

Evaporator

Caution

Non-approved tools or materials such as leak sealing

additives can cause damage or malfunctions in the

system.

Only use tools and materials approved by the

manufactu ...

Parking

First read and observe the introductory information

and safety warnings Please adhere to relevant legislation when

stopping and parking your vehicle.

Stopping the vehicle

The steps should only be carried out in the specified order.

Stop the vehicle on a suitable surface .

Depre ...

Battery, Charging with Battery Charger -VAS5903

Special tools and workshop equipment

required

Battery Charger -VAS5903-

WARNING

Risk of injury. Follow all Warnings and Safety

Precautions. Refer to

→ ...

© 2016-2026 Copyright www.vwpolo.net

Note

Note Note

Note Note

Note One-Part Clean Spray Can -LLS MAX 112-, Aqua Premium System

One-Part Clean Spray Can -LLS MAX 112-, Aqua Premium System Two-Part Clear Coat

Two-Part Clear Coat

Caution

Caution WARNING

WARNING