Volkswagen Polo Service & Repair Manual: Two-Part Clear Coat

| Two-Part Clear Coat -LLS MAX 210- |

| The Two-Part Clear Coat - LLS MAX 210- is a high-gloss

two-component clear coat for long-lasting sealing of painted

surfaces. It is specially developed for part- and repair paint

jobs. This product is characterized by its resistance to weather

and chemicals, an exceptional gasoline resistance and good

polishability. The two-part clear coat has good flow properties

and tends to be used for larger surfaces (one to two vehicle

body parts). The raw material base is acrylic resin. The

hardener contains isocyanate. |

| Constant atomizing pressure |

| Excellent filling ability |

| Application area: touch up in part- and repair paint job

area |

| Professional painting result |

Note Note

| For work safety, wear appropriate, personal protective

equipment: |

| Breathing mask type: A2/P2 |

| Latex or nitrile protective gloves, for example |

| Solvent- and water-soluble base paint systems |

| Old paints, cleaned and sanded |

|

|

|

| Base Surface |

Suitability |

| One-part base paint |

+++ |

| One-part water-based

paint |

+++ |

| Two-part top coat |

++ |

| Old paints |

+++ |

| Activating the Two-Part Spray Can: |

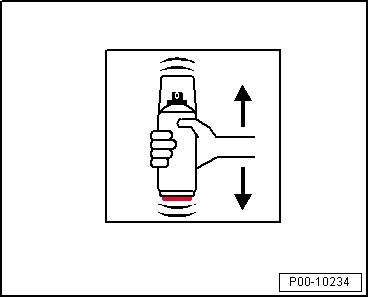

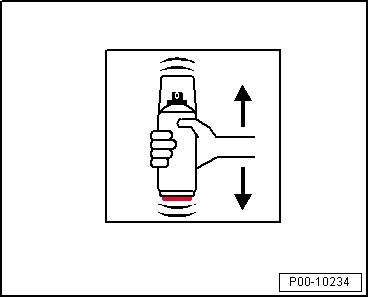

| – |

Before activating, thoroughly shake the can for two minutes. |

|

|

|

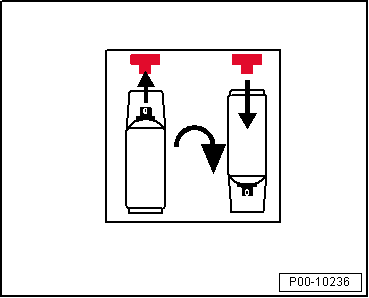

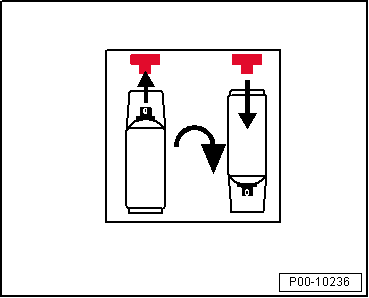

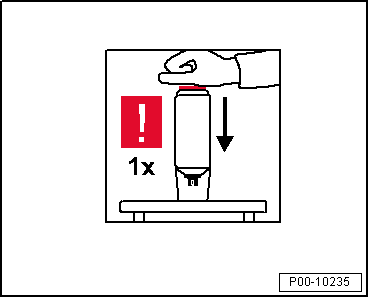

| – |

Remove the red push button on the cap and set it on the

valve for the hardener mixture on the bottom of the can. |

|

|

|

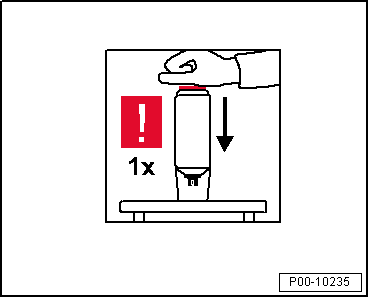

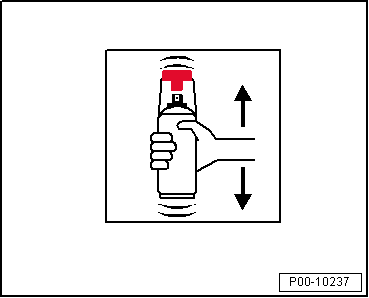

| – |

Press in the valve for the hardener mixture. Make sure when

pressing down the valve for the hardener mixture that the can

(with the cap) is upside down. |

|

|

|

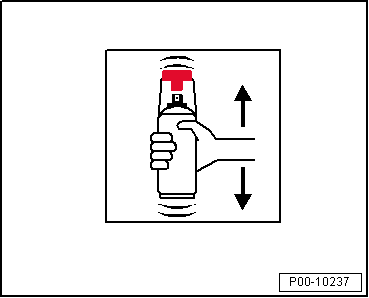

| – |

After activating, thoroughly shake the can again for at

least two minutes. |

|

|

|

| Processing time/pot life: |

| – |

48 hours at +20 °C (68 °F) |

Note Note

| The processing time depends on the ambient temperature.

Higher temperatures lead to a shortened pot life. Lower

temperatures lead to a longer pot life. |

|

|

|

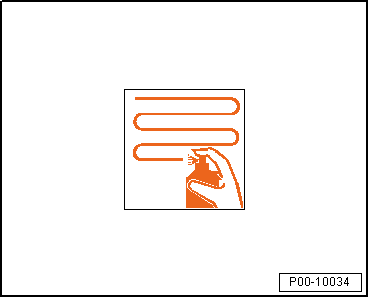

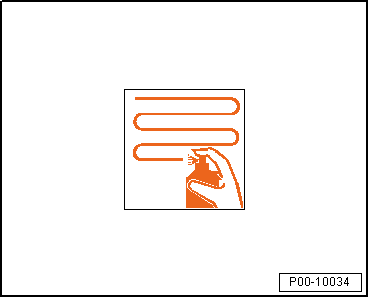

| – |

Apply one to two spray applications to cover (each

application 30 µm) with a 10 to 15 minute intermediate

ventilation time, depending on temperature. |

| – |

Maintain a distance of 20 to 25 cm. |

Note Note

| If the spraying procedure is interrupted, make sure that the

valve above the spray head is empty to prevent any nozzle

blockage. |

|

|

|

| Air drying at +20 °C (68 °F) room temperature is 12 hours. |

|

|

|

| The drying time with forced drying is at least 10 to 15

minutes. |

| Forced drying is at +60 °C (140 °F) object temperature for

35 to 40 minutes. |

|

|

|

| The drying time for IR drying is a minimum of 10 to 15

minutes. |

|

|

|

| Solid content: |

33.8 % in relation to

thinned paint |

| Yield: |

Approximately 0.5 to 0.75

m²/spray can with approximately 30-50 μm dry layer thickness |

| Gloss level: |

High-gloss |

| VOC value: |

668 g/L, 258 g/can |

| The guaranteed shelf life is 24 months from production date.

Use no later than the date indicated on the label and store in

original container at +20 °C (68 °F). |

|

|

|

Definition:

Two-Part Filler -LLS MAX 202 M2-, medium gray

Edition 03/2013

Product Description

...

Definition:

Two-Part Epoxy Primer Filler -LLS MAX 220 M1-, beige (250

ml)

Two-Part Epoxy Primer Filler -LLS MAX 22 ...

Other materials:

Driving with an automatic gearbox

First read and observe the introductory information

and safety warnings The gearbox changes the forward gears up

and down automatically.

Driving down hills

The steeper the gradient, the lower the gear you will need. Lower gears increase

the braking effect of the engine. Never allow the veh ...

Wiring Harness Repair Set -VAS1978

The Wiring Harness Repair Set -VAS1978- makes optimal repair

quality possible in the realm of vehicle electronics. Using the

tools, repairs affecting harness connectors and for breaks in

wiring can be performed. For this purpose, complete repair wires

wi ...

Side view

Fig. 1 Overview of the right side of

the vehicle Positions ③, ④, ⑤ and ⑤ are also at the same position on the left

side of the vehicle.

Key for :

Tank flap

Roof aerial

Attachment points for the mounts and

roof carrier

Door release lever

Exterior mirrors

Jacking p ...

© 2016-2026 Copyright www.vwpolo.net

Note

Note Note

Note Note

Note Two-Part Filler

Two-Part Filler Two-Part Epoxy Primer Filler

Two-Part Epoxy Primer Filler

Caution

Caution WARNING

WARNING