Volkswagen Polo Service & Repair Manual: Fiber-Optic Cable, Assembling

| Special tools and workshop equipment

required |

| Fiber-Optic Conductor Repair Set -VAS6223A- |

| Hose Cutting Pliers -VAS6228- |

| Vehicle Diagnostic Tester |

| It is very difficult to find the exact location of the

problem. Replace the damaged fiber-optic cable and lay a new

wire parallel to the defective fiber-optic cable. |

Note Note

| Select the damaged fiber-optic cable components with the

“Guided Fault Finding” or “Guided Functions” from the Vehicle

Diagnostic Tester menu options. |

| A fiber-optic cable that needs repair is represented by a

“yellow” color. |

| – |

Choose “Guided Fault Finding” or “Guided Functions” in the

Vehicle Diagnostic Tester. Refer to Vehicle Diagnostic Tester. |

| – |

Assemble the fiber-optic cable. Refer to

→ Chapter „Fiber-Optic Cable, Assembling“. |

Caution

Caution

| Do not bend the fiber-optic cable too much. The

bending radius must be no less than 25 mm. |

| Fiber optic cables must not be routed over sharp

edges. |

| The fiber-optic cable must not be dirty or touched

with bare fingers. |

| Fiber optic cables may not be heated. |

| It is not permitted to twist together 2 fiber optic

cables or one fiber optic cable with a copper wire. |

| Protect the connector and the connection box from

dust. Place the cap on the trunk. |

|

Caution

Caution

| Do not bend the fiber-optic cable too much. The

bending radius must be no less than 25 mm. |

| Fiber optic cables must not be routed over sharp

edges. |

| The fiber-optic cable must not be dirty or touched

with bare fingers. |

| Fiber optic cables may not be heated. |

| It is not permitted to twist together 2 fiber optic

cables or one fiber optic cable with a copper wire. |

| Protect the connector and the connection box from

dust. Place the cap on the trunk. |

|

|

|

|

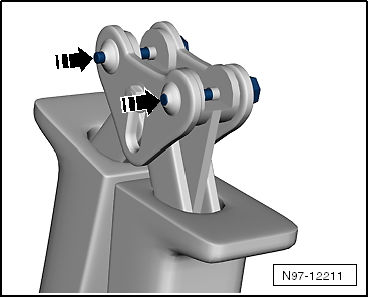

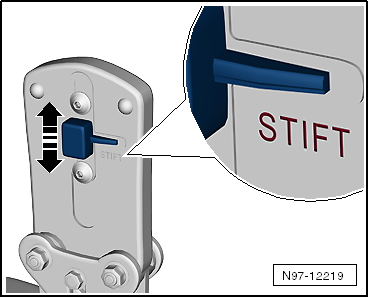

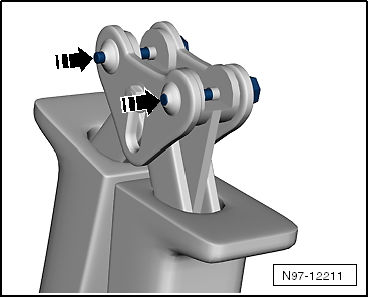

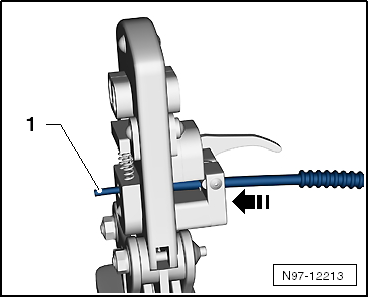

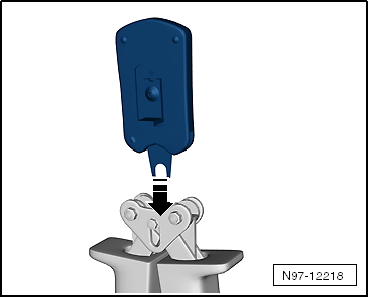

| Mount the Tool Head for the Fiber-Optic Repair Set - Pliers

-VAS6223/1-. |

|

|

|

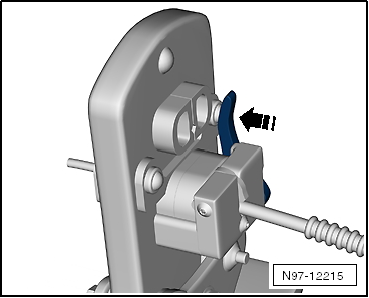

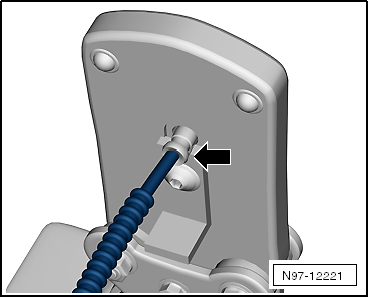

| – |

Remove the locking pin -arrows-. |

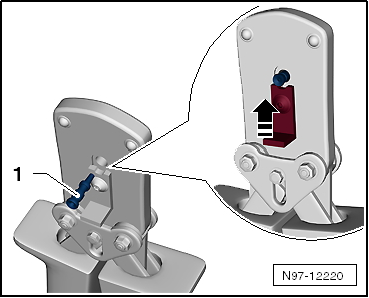

| – |

Remove the tool set -arrow- and

pull the locking pin back. |

|

|

|

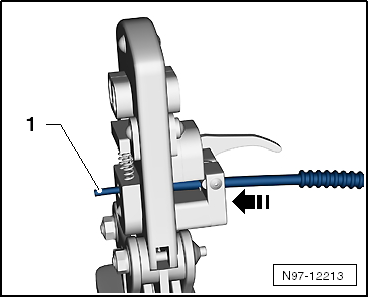

| Fiber Optic Cable, Cutting to Length |

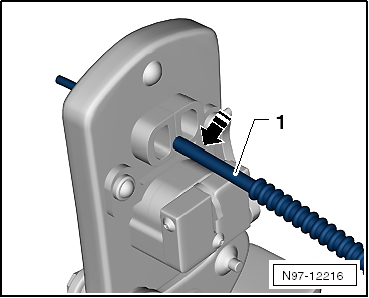

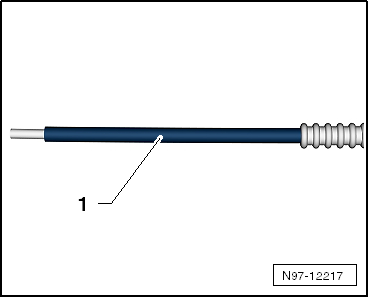

| – |

Establish length of fiber optic cable required. |

| – |

Open the Fiber-Optic Repair Set - Pliers -VAS6223/1- and lay

the fiber-optic cable -1- in the

mount. |

| – |

Close the Fiber-Optic Repair Set - Pliers -VAS6223/1- to cut

the fiber-optic cable lengths. |

|

|

|

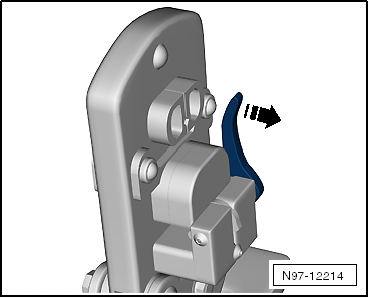

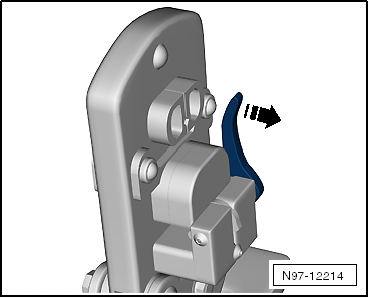

| – |

Open the Fiber-Optic Repair Set - Pliers -VAS6223/1-. |

| – |

Position the wire stripper in the lower position

-arrow-. |

| – |

Insert fiber-optic cable into the stripping station. |

| The end of the fiber-optic cable must be flush with the rear

side of the cutting pliers. |

|

|

|

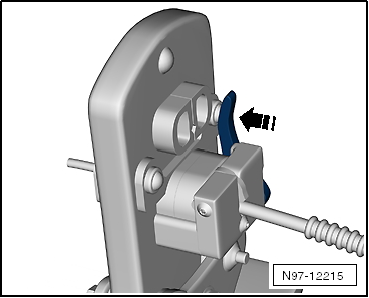

| – |

Close the Fiber-Optic Repair Set - Pliers -VAS6223/1- until

the stop and keep closed. |

| – |

Bend the wire stripper upward -arrow-

and remove the fiber-optic cable. |

|

|

|

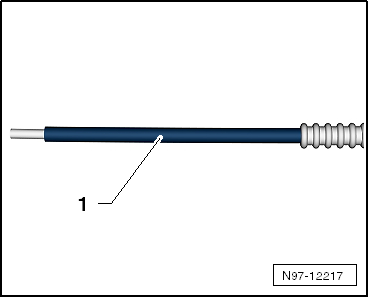

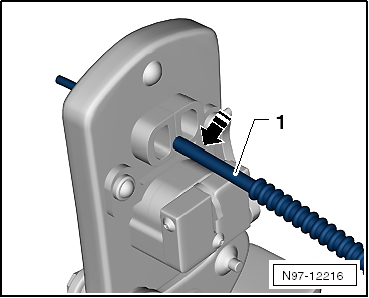

| Precision Cutting (Production of Optical End Face) |

| – |

Push the fiber-optic cable -1-

into the cutting station. |

| Insulation must make contact with cutting point stop. |

|

|

|

| – |

Close the Fiber-Optic Repair Set - Pliers -VAS6223/1- and

remove the wire. |

| – |

Visually inspect the wire -1-

to make sure that it was cut correctly and that there are no

burrs on the front surface. |

Note Note

| Fiber-optic cable is only to be placed on an absolutely

clean surface or held in hand. |

| Use the cap if there is a risk of the fiber-optic cable

surface becoming dirty. |

|

|

|

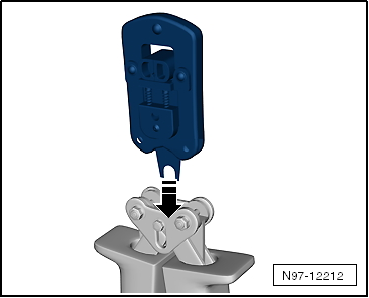

| Attaching Brass Pin Contact to Fiber-Optic Cable |

|

|

|

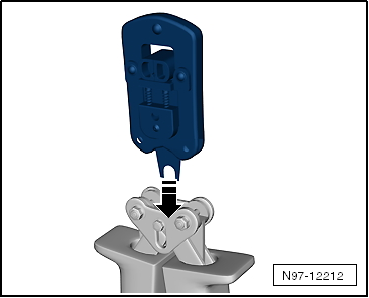

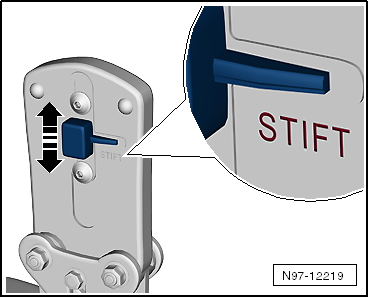

| – |

Change tool head -arrow-. |

| – |

Slide the safeguard on the Fiber-Optic Repair Set - Pliers

-VAS6223/1- in direction of -arrow-

so that the word “Stift” (pin) is legible. |

|

|

|

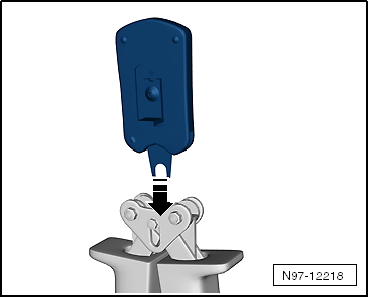

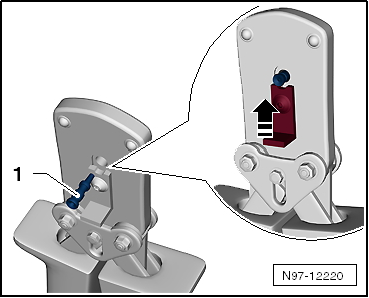

| – |

Insert a brass pin contact -1-

in the mount. |

| – |

Close the securing lever on the Fiber-Optic Repair Set -

Pliers -VAS6223/1- in direction of -arrow-. |

|

|

|

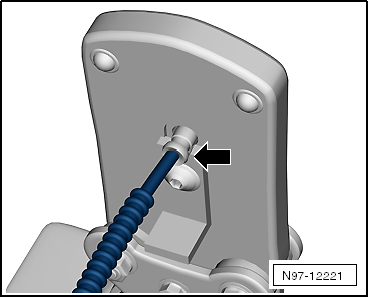

| – |

Insert the fiber-optic cable into the brass pin contact

-arrow- all the way up to the

threaded stop and then close the Fiber-Optic Repair Set - Pliers

-VAS6223/1-. |

| – |

Open the fiber-optic cable pliers and remove the fiber-optic

cable along with the brass contact pin. |

Caution

Caution

| Do not excessively bend or kink the fiber-optic

cables (minimum bending radius 25 mm). |

|

|

|

|

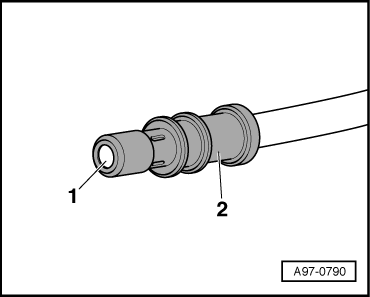

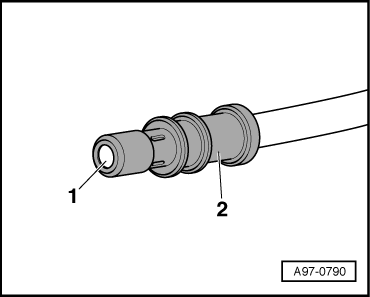

| – |

Make sure the brass pin contact -2-

is secured properly on the fiber-optic cable

-1-. |

| 4 crimped points must be visible on the brass connecting

pin. |

| The brass pin contact must not be able to be removed by hand

from fiber-optic cable. |

| The front surface of the fiber-optic cable is 0.01 to 0.1 mm

behind the brass pin contact (visual check). |

Note Note

| Connector couplings are available for connecting the

fiber-optic cables. Refer to Parts Catalog. |

| To install the new fiber optic cable in wiring harness

connector. Refer to

→ Chapter „Fiber-Optic Cable, Disconnecting from Wiring Harness

Connector“. |

|

|

|

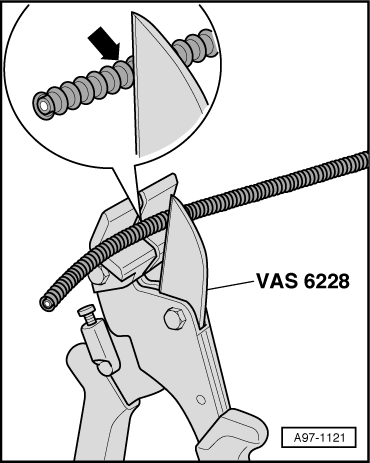

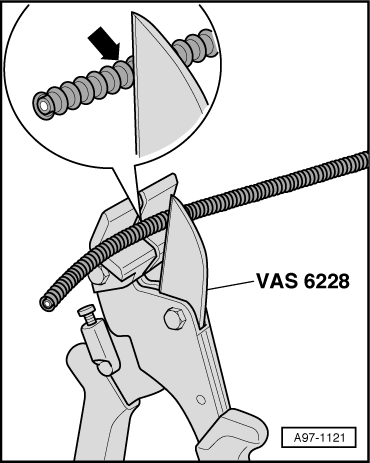

| Corrugated Tube, Install on Fiber Optic Cable |

| – |

Cut corrugated tube to appropriate length. |

| Use the Hose Cutting Pliers -VAS6228- or a sharp knife for

cutting. |

| The corrugated tube must not be cut through using a side

cutter under any circumstances |

| The corrugated tube must be cut on the wave peak

-arrow-, not in the wave trough. |

| The corrugated tube must audibly engage in the fiber-optic

cable housing when installing. |

|

|

|

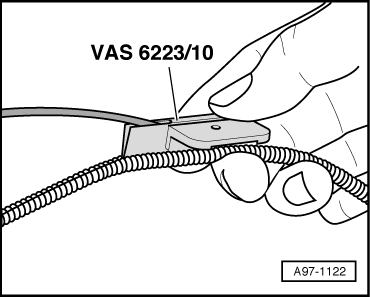

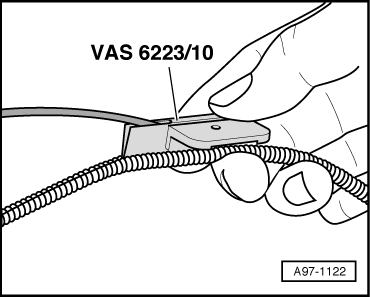

| – |

Guide the fiber-optic cable into the Fiber-Optic Repair Set

- Tube Tool -VAS6223/10- as shown. |

| – |

Position corrugated tube assembly pliers on slot on the

tube. |

| – |

Position crimping pliers for fiber-optic cable at slot of

corrugated tube. The fiber optic cable is then routed in the

corrugated tube. |

|

|

|

Removing

–

Unplug connector for fiber optic cable from appropriate

control unit.

–

Release the loc ...

Other materials:

Support Mode with Battery Charger -VAS5900

General Information

The support mode provides the vehicle electrical system with

voltage when the battery is removed or disconnected.

For more information. Refer to Battery Charger -VAS5900-

Operating Instructions.

...

Centre armrest

Fig. 42 Front centre armrest

First read and observe the introductory information

and safety warnings

To lift, pull the centre armrest up gradually in the direction of the

arrow .

To lower, pull the centre armrest all the way up. Then lower the centre

armrest.

WARNING

The centre armrest ...

Exterior Lights, Switches

HID Headlamp Usage and Safety Precautions

Special tools and workshop equipment

required

Protective Eyewear

Gloves

–

Note the following if working with HID headlamps:

...

© 2016-2026 Copyright www.vwpolo.net

Note

Note Note

Note Note

Note Fiber-Optic Cable, Disconnecting from Wiring Harness Connector

Fiber-Optic Cable, Disconnecting from Wiring Harness Connector

Caution

Caution