Volkswagen Polo Service & Repair Manual: Airbag and Belt Tensioner Wire Repair Information

Note Note

| Observe general notes for repairs on the vehicle electrical

system. Refer to

→ Chapter „Vehicle Electrical System, General Repair

Information“. |

| In addition to the general repairs on wiring harnesses, the

following methods and instructions must be observed for repairs

on airbag- and seat belt tensioner wires |

WARNING

WARNING

| The airbag and seat belt tensioner system can fail. |

| Faulty repairs performed on airbag and seat belt

tensioner system can lead to malfunction in passenger

protection. |

| When performing repairs on airbag and seat belt

tensioner wiring harness, use only terminals, connectors

and wires designated for it. Refer to the Parts Catalog. |

|

Note Note

| Air bag wires and the safety belt tensioner wiring harness

may repaired only with the Wiring Harness Repair Set -VAS1978B-

and previous versions. |

| Observe general notes for repairs on the vehicle electrical

system. Refer to

→ Chapter „Vehicle Electrical System, General Repair

Information“. |

| Pay attention to decals designating high voltage components.

When performing repairs, the residual voltage must be

discharged. Refer to

→ Body Interior; Rep. Gr.69. |

|

|

|

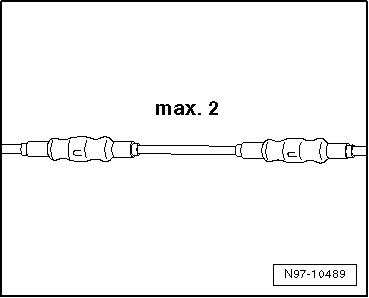

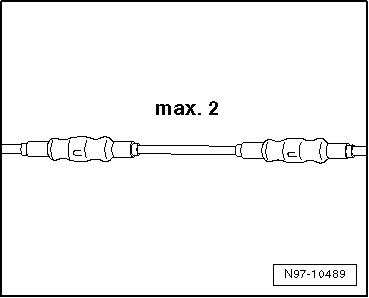

| A maximum of two repairs may be performed when repairing

wires of airbag- and seat belt tensioner system. Repairs

increase the electrical resistance in the wire and may trigger

malfunctions in the system On Board Diagnostic (OBD). |

| When repairing wiring harness of airbag- and seat belt

tensioner system, the crimp connectors must always be

heat-shrunk to prevent corrosion. |

| Do not wrap the repair point again into the vehicle-specific

wiring harness and mark the repair point quite visibly with

yellow insulating tape. |

|

|

|

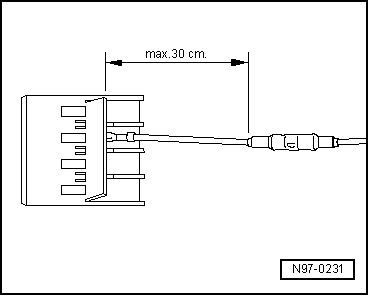

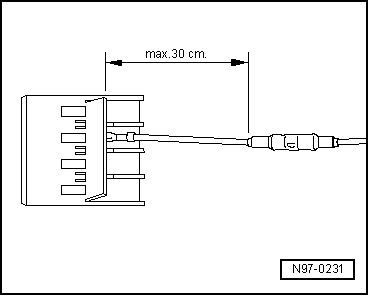

| Repairs in the area of the airbag or seat belt tensioner

should be performed a maximum of 30 cm from the next contact

housing. Together with the identification via yellow insulating

tape, this procedure makes it possible to obtain a quick

overview of previously performed repairs. |

| Wires to the deploying units (airbags) have a wire-twisting

with a length of lay of 20 mm ± 5 mm in series production. This

length of lay is guaranteed via the norm part numbers for wire

pairs in series production and must be observed strictly for the

repair lengths of twisted wires. |

|

|

|

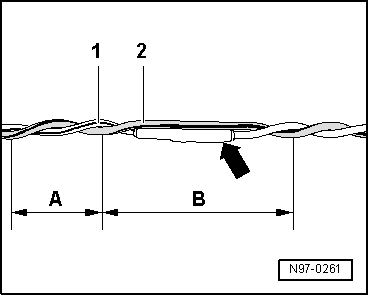

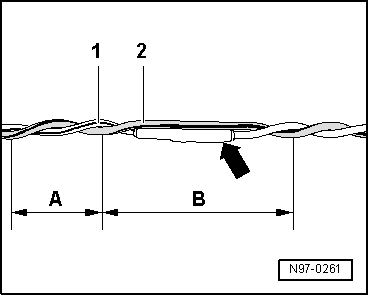

| During repair work, wires to deploying units (airbags) must

have the same length. When twisting together wires

-1 and 2-, length of lay of

-A- = 20 mm ±5 must be strictly

observed. |

| While doing this, no section of the wire, for example, in

area of crimp connectors -arrow-,

may be greater than B = 100 mm without twisting of the wires. |

|

|

|

Unshielded two-strand wiring -1-

and -2- with a cross section of

0.35 mm2 or 0.5 mm2

can be used as CAN bus wiring.

The color ...

Other materials:

Tire Sidewall Swelling

A swelling in the flank of the tire indicates that the

substructure of the carcass has been damaged.

Typical causes for such damage include, for example, driving

over curbs at a sharp angle.

...

Two-Part HS Wet-in-Wet Filler

Definition:

Two-Part HS Wet-in-Wet Filler -LVM 013 008 A4-, light gray

Two-Part HS Wet-in-Wet Filler -LVM 013 905 A4-, black

Edition 03/2015

Product Description

...

Headlamp Washer System

The following hose connection types are used for connecting

hoses to pumps and spray nozzles or as separating points

–

Disconnect by depressing clip

-1--arrow- and then separating coupling ...

© 2016-2026 Copyright www.vwpolo.net

Note

Note Note

Note CAN Bus Wires, Repairing

CAN Bus Wires, Repairing

WARNING

WARNING