Volkswagen Polo Service & Repair Manual: Tire Pressure Monitoring Sensor without Metal Valve, Removing and

Installing, Service Version

| Special tools and workshop equipment

required |

| – |

Remove the tire from the disc wheel. Refer to

→ Chapter „Tires, Mounting“. |

|

|

|

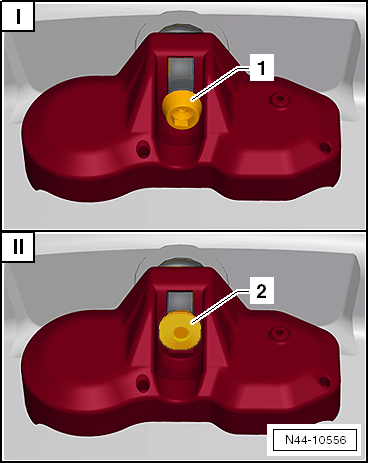

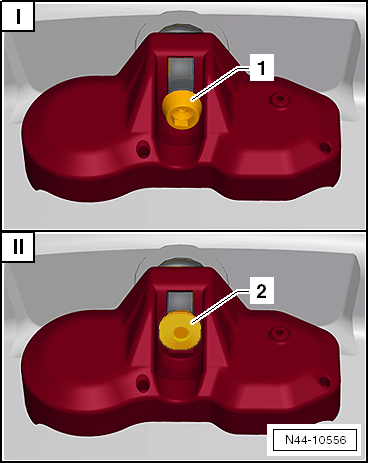

| See Which Version is Installed Before Starting Any Work. |

| The tire pressure monitoring sensor is attached to the valve

with an inner TORX screw -1- on the

Service version. |

| If the service version is installed, the following repair

procedure must be used. Refer to

→ Anchor. |

| II - Vehicles Before Customer Delivery |

| The tire pressure monitoring sensor is attached to the valve

with a square screw with a flat head -2-

on vehicles before customer delivery. |

| If the production version is installed, the following repair

procedure must be used. Refer to

→ Anchor. |

| – |

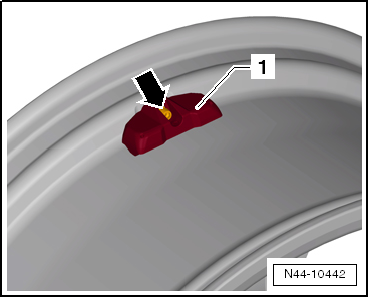

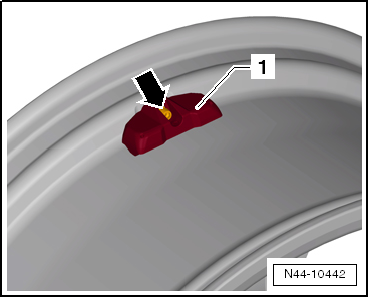

Remove the screw

-arrow- from the tire pressure

monitoring sensor -1-. |

|

|

|

| – |

Counterhold metal valve using retainer (for example 2 mm

spiral bore) while doing so. |

Caution

Caution

| Clean the valve opening before installing the Tire

Pressure Monitoring Sensor. |

|

|

|

|

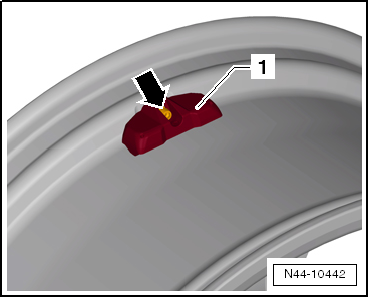

| – |

Press the tire pressure monitoring sensor

-1- onto the disc wheel (rim) and

tighten -arrow-. |

| – |

Counterhold metal valve using retainer (for example 2 mm

spiral bore) while doing so. |

Note Note

| Visually check the valve after installing it and make sure

it is tight. The tire pressure monitoring sensor

-1- must not have any play when it

is installed and it must touch the supports in the rim bed. |

| Do not tighten the valve again to the tightening

specification after it has been installed. |

| Tightening Specifications |

| Refer to

→ Chapter „Overview - Tire Pressure Monitoring Sensor without

Valve“ |

|

|

|

Removing

–

Remove the union nut -1-.

–

Remove Tire Pressure Moni ...

Special tools and workshop equipment

required

Torque Wrench -VAG1410-

Perform the Following:

Remo ...

Other materials:

Waxing and polishing the vehicle

First read and observe the introductory information

and safety warningsWaxing

Waxing protects the paintwork. You will need to re-wax the vehicle with a good

hard wax if water no longer clearly forms small drops

and runs off the paintwork when it is clean.

Even if a wax solution is used regul ...

Operating ParkPilot

Fig. 120 In the rear bumper: ParkPilot

ultrasound sensors

First read and observe the introductory information

and safety warnings The ParkPilot uses ultraound sensors to

determine the distance between the rear bumper and an obstacle. There are 4 ultrasound

sensors in the rear bumper ...

Rear towing eye

Fig. 194 In the rear bumper on the

right-hand side: removal of the covers for the towing eye

Fig. 195 In the rear bumper:

removal of the covers for the towing eye

First read and observe the introductory

information and safety warnings

There is a fixed towing eye located underneath the rea ...

© 2016-2026 Copyright www.vwpolo.net

Note

Note Tire Pressure Monitoring Sensor with Valve, Removing and Installing

Tire Pressure Monitoring Sensor with Valve, Removing and Installing Tire Pressure Monitoring Sensor without Valve, Removing and Installing,

Vehicle Before Customer Delivery

Tire Pressure Monitoring Sensor without Valve, Removing and Installing,

Vehicle Before Customer Delivery

Caution

Caution