Volkswagen Polo Service & Repair Manual: Threaded Connections, Repairing

| Special tools and workshop equipment

required |

| Torque Wrench 1331 5-50Nm -VAG1331- |

Note Note

| Do not use rust remover, contact spray or grease because the

lack of friction will cause the torque to be exceeded when

installing and this will lead to the threaded connection

breaking. |

| The gray sanding pads are for slight contamination and

suitable for "soft surfaces". The red sanding pads are for heavy

contamination and suitable for "hard surfaces". |

WARNING

WARNING

| Risk of injury. Follow all Warnings and Safety

Precautions. Refer to

→ Chapter „Warnings and Safety Precautions“. |

|

|

|

|

Special tools and workshop equipment

required

Torque Wrench 1331 5-50Nm -VAG1331-

Note

Do not use r ...

Special tools and workshop equipment

required

Torque Wrench 1331 5-50Nm -VAG1331-

The Contact Surface Cleaning Set -VAS6 ...

Other materials:

Refrigerant Circuit with Expansion Valve

A-Low pressure side of refrigerant circuit.

B-High pressure side of refrigerant circuit.

Component

Aggregate State of Refrigerant

Pressure bar (psi) Positive Pressure

Temperature

...

Engine oil specification

First read and observe the introductory information

and safety warningsThe engine oil used must correspond exactly to specifications.

The correct engine oil is important for the function and service life of the

engine. A special high quality multigrade oil has been filled at the factory and

t ...

Tread Depth, Measuring

Note

When measuring tread depth, take measurements in the main

grooves.

Do not take measurements at the tread wear indicator.

Tread depth of a tire must be mea ...

© 2016-2026 Copyright www.vwpolo.net

Note

Note Note

Note Note

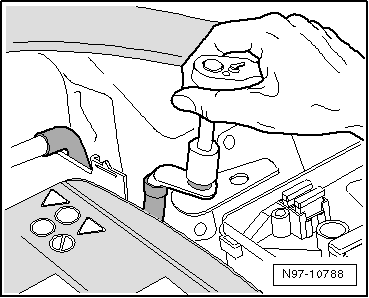

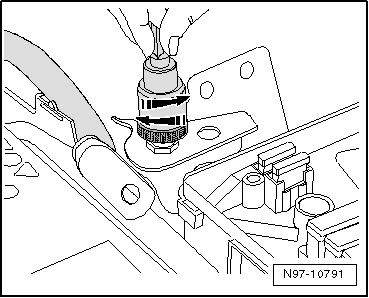

Note Wiring Eyelets, Repairing

Wiring Eyelets, Repairing Battery Terminal Clamp and Battery Terminal, Cleaning

Battery Terminal Clamp and Battery Terminal, Cleaning

WARNING

WARNING Caution

Caution