Volkswagen Polo Service & Repair Manual: Aqua Premium System, Touch-Up System for Two Layer Colors

| Product Description/Objective |

| To achieve an optically flawless color shade transition in

the blended area or adjacent parts, for example fender/door. |

| For plastic surfaces prime with Glazing Adhesion Promoter -

ALO 822 000 10- and rework with elastified Two-part HS. |

|

|

|

| Pre-treatment of base surfaces: |

| – |

Clean the factory or old paint or two-part HS filler

thoroughly with Silicone Remover -LVM 020 000 A5- or Silicone

Remover, Long -LVM 020 100 A5-. |

|

|

|

| – |

Sand the repair area with P500-P600 grit sandpaper or

wet-sand with water-resistant P800-1000 sandpaper. |

|

|

|

| – |

Sand the adjacent area (around the vehicle parts and the

repair area) thoroughly with P1000-3000 sandpaper, only wet

sand. |

Note Note

| If beading, edges or grip recesses are present, use a

sanding pad beforehand. |

|

|

|

| – |

Clean the entire surface thoroughly with Silicone Remover -LVM

020 000 A5- to remove dust, sanding residue and other dirt. |

| – |

Wipe off any residual silicone remover with a lint-free

cloth, leaving no streaks. |

|

|

|

| – |

Allow wet-sanded surfaces and cleaned surfaces to dry

completely. |

| When using a dust extraction, use next generation towels

with an effective light adhesive formula to minimize the risk of

chemical or adhesive residue (for example, Dust Cloth

-VAS6177-). Refer to

→ Chapter „Dust Cloth -VAS6177-“. |

| Insulate sanded-through areas with Two-Part Wash Primer -LHV

043 000 A2- and then fill with Two-Part HS Performance Filler. |

|

|

|

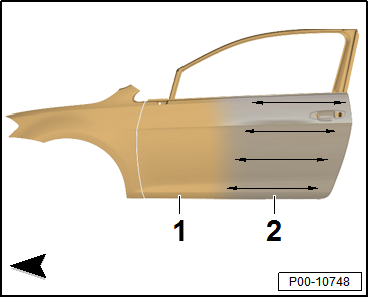

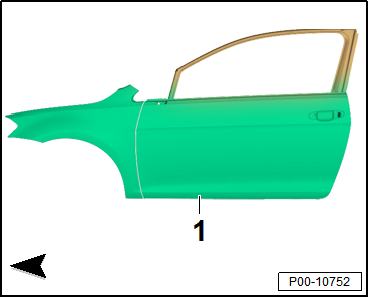

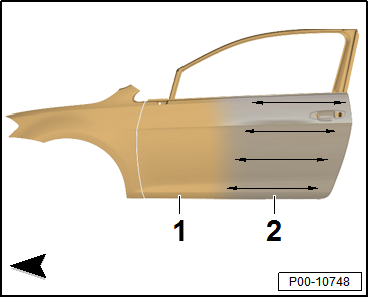

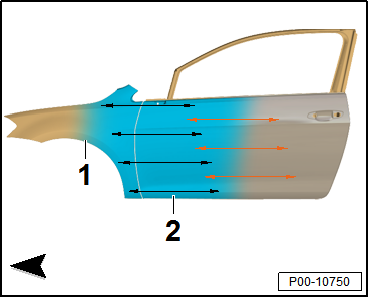

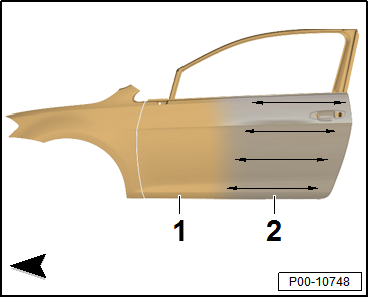

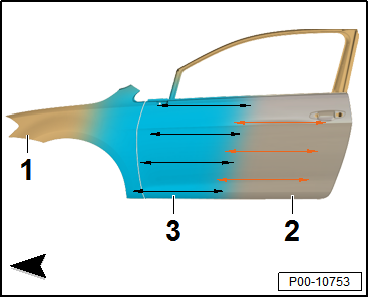

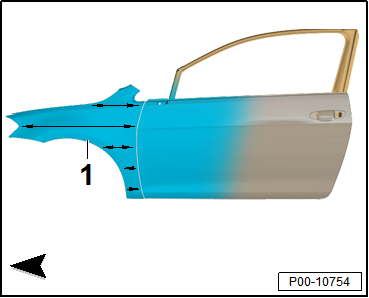

| Repair process, touch-up the neighboring surfaces (for

example color matching fender/door) |

| – |

Apply 1-2 preliminary spray applications of the Touch-Up

Additive For Aqua Premium -LVM 035 100 A3--2-

in the blended area with normal spray pressure on the old

paint/filled surface -1-. |

Note Note

| Pay attention that the blended area is large enough. |

|

|

|

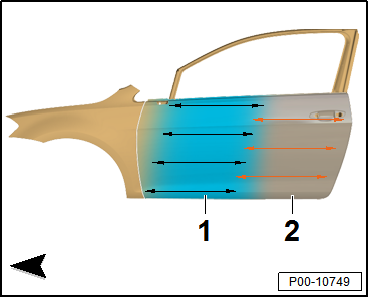

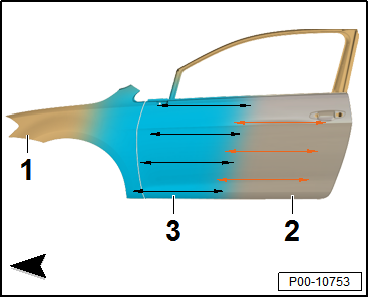

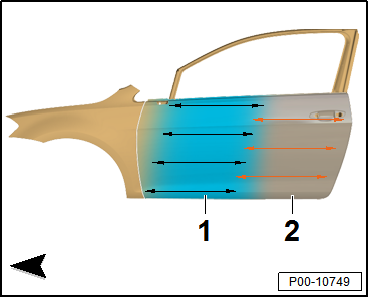

| – |

Then the first base paint spray application

-1- is lightly applied from the

blended area into the wet touch-up additive

-2-. |

|

|

|

| – |

In the second step a further reduced spray application

-2- follows without a drying time.

Pay attention that the spray application is applied in the area

previously shifted forward -1- to

archive an even effect. |

|

|

|

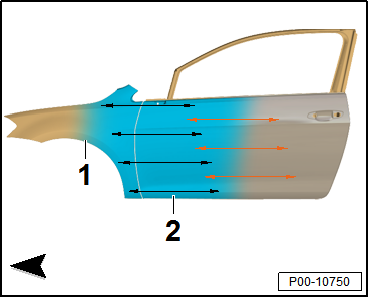

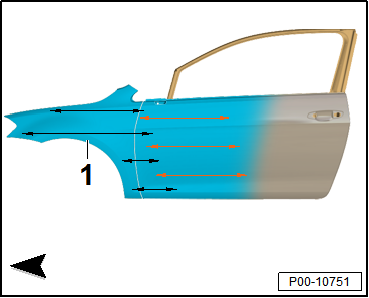

| – |

After the touch-up painting the connection area and the

remaining surfaces (starting from the new part)

-1- in 1.5 spray applications

(standard process) are painted. |

|

|

|

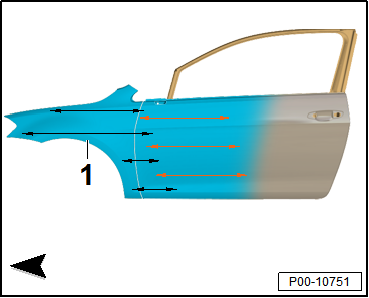

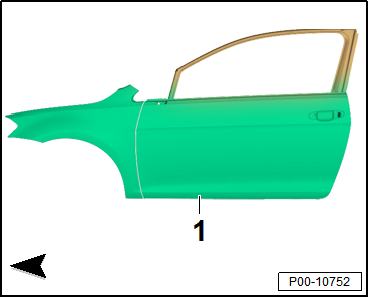

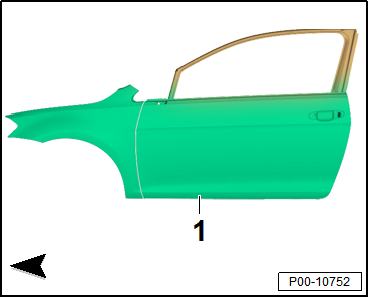

| – |

After ventilating, apply a two-part HS clear coat

-1- over the entire repair surface. |

|

|

|

| Repair process, touch-up the neighboring surfaces (for

example color matching fender/door, alternative method for solid

and dark effect color shades). |

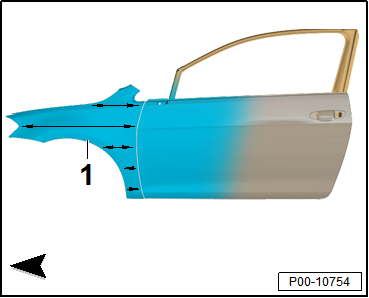

| – |

Apply 1-2 preliminary spray applications of the Touch-Up

Additive For Aqua Premium -LVM 035 100 A3--2-

in the blended area with normal spray pressure on the old

paint/filled surface -1-. |

Note Note

| Pay attention that the blended area is large enough. |

|

|

|

| – |

Then apply the first base paint spray application

-3- from the blended area (starting

from the new part) to the edge of the wet touch-up additive

-2-. Immediately after that, apply

the half effect/finish spray application onto the wet touch-up

additive -2- and to the new part

-1-, from a distance. |

|

|

|

| – |

After touch-up painting the base paint application

-1- takes place on the remaining

surfaces in 1.5 spray applications (standard process). |

|

|

|

| – |

After ventilating, apply a two-part HS clear coat

-1- over the entire repair surface. |

Note Note

| Starting with the first spray application, it is recommended

to even out the subsequent repair area spray applications

starting from the touch-up area that is farthest out. For that

reason, the subsequent spray applications should always be

remain inside the previous spray application in order to archive

an even effect. |

| While processing the Aqua premium water-based base paint,

the spray gun material flow/trigger remains completely open. |

| The spraying pressure for the effect spray application can

vary between 1.5 and 2.0 bar depending on the size of the

object. |

|

|

|

| Repair process, touching-up minimal damage for example

clever repair. |

Note Note

| The repair/filler area should be kept as small as possible. |

| For most colors, use the adjusted water-based base paint. |

| It is recommended for colors with a high percentage of metal

to adjust the Aqua premium water-based base paint in a 1:1 ratio

with Touch-Up Additive for Aqua Premium -LVM 035 100 A3- + 10 %

Flop Control -LWM 085 386 A2- (Additive For Aqua Premium -LVM

035 200/301- is not required). Use the Aqua Premium dipstick for

clever repair. |

| Depending on the color and covering capacity, apply 3-5

spray applications of this mixture with reduced pressure

(0.8-1.5 bar) to the repair area/run-off area. Make sure that

each spray application is performed a little bit further and

allowed to ventilate and matt. The ventilation time can be

accelerated by blowing. |

|

|

|

| – |

After an appropriate final ventilation time, the clear coat

can be applied. |

Note Note

| While processing the Aqua premium water-based base paint,

the spray gun material flow/trigger remains completely open. |

| For efficient ventilating and drying, stationary blowing

devices or forced drying (for example heated drying) are

recommended. |

| The spray devices should be suitable for use with

water-soluble products; see manufacturer's information. |

| The Aqua Premium mixing paints can only be used within the

color tone formulas. |

| When processing individual mixing paints on their own, major

deviations from the information given in the application

instructions are possible. |

| Rinse before and after using with Aquaplus Purified Water -LVW

010 000 A5-. Then rinse with Nitrocellulose Thinner -LVE 856 000

A3-. |

| Collect liquid waste from water-soluble products and

separate from liquid waste from conventional products. When

mixing materials, disposal may no longer be possible, which is

difficult and costly. |

|

|

|

| Personal Protective Equipment: |

| Note the safety data sheets |

| Wear the personal protective equipment during application |

|

|

|

This universal painting system enables you to safely and

simply paint all plastic parts which can be usually found on the

exterior. (Plastic types: PP, EPDM, ABS, PC, ...

Product Description/Objective

To achieve an optically flawless color shade transition in

the blended area or adjacent parts, for example fender/door. ...

Other materials:

Switching lights on and off

Fig. 68 Next to the steering wheel: examples

of the various light switches

First read and observe the introductory information

and safety warnings

Observe any country-specific regulations when using vehicle lighting.

In vehicles with a factory-fitted towing bracket, the vehicle's

rear fog ...

Overview of the front passenger side

Fig. 9 Overview of the front passenger

side (left-hand drive vehicles). The controls are mirrored in right-hand drive

vehicles

Key for :

Vent

,

Location of front passenger front airbag

in the dash panel

Key-operated switch in the stowage

compartment for switch ...

Hill Hold Assist

First read and observe the introductory information

and safety warnings The Hill Hold Assist function actively holds

the vehicle when pulling away on an incline.

The Hill Hold Assist function is automatically activated if the following conditions

are met

Cond ...

© 2016-2025 Copyright www.vwpolo.net

Note

Note Note

Note Note

Note Note

Note Note

Note Note

Note Paint System for Plastic Parts

Paint System for Plastic Parts Aqua Premium System, Touch-Up System for Three Layer Colors

Aqua Premium System, Touch-Up System for Three Layer Colors