Volkswagen Polo Service & Repair Manual: Aqua Premium System, Touch-Up System for Three Layer Colors

| Product Description/Objective |

| To achieve an optically flawless color shade transition in

the blended area or adjacent parts, for example fender/door. |

| For plastic surfaces prime with Glazing Adhesion Promoter -ALO

822 000 10- and rework with elastified Two-part HS filler

(Two-Part Plastic Adhesive Filler -LKF 696 009 A2-/-LKF 696 040

A2-). |

|

|

|

| Pre-treatment of base surfaces: |

| – |

Clean the factory or old paint or two-part HS filler

thoroughly with Silicone Remover -LVM 020 000 A5- or Silicone

Remover, Long -LVM 020 100 A5-. |

|

|

|

| – |

Sand the repair area with P500-P600 grit sandpaper or

wet-sand with water-resistant P800-1000 sandpaper. |

|

|

|

| – |

Sand the adjacent area (around the vehicle parts and the

repair area) thoroughly with P1000-3000 sandpaper, only wet

sand. |

Note Note

| If beading, edges or grip recesses are present, use a

sanding pad beforehand. |

|

|

|

| – |

Clean the entire surface thoroughly with Silicone Remover -LVM

020 000 A5- to remove dust, sanding residue and other dirt. |

| – |

Wipe off any residual silicone remover with a lint-free

cloth, leaving no streaks. |

|

|

|

| – |

Allow wet-sanded surfaces and cleaned surfaces to dry

completely. |

| When using a dust extraction, use next generation towels

with an effective light adhesive formula to minimize the risk of

chemical or adhesive residue (for example, Dust Cloth

-VAS6177-). Refer to

→ Chapter „Dust Cloth -VAS6177-“. |

| Insulate sanded-through areas with Two-Part Wash Primer -LHV

043 000 A2- and then fill with Two-Part HS Performance Filler. |

| Test spraying on sheet metal is strongly recommended. |

|

|

|

| Touching-Up Three Layer Colors: |

| Adjusting the touch-up additives: |

| – |

Adjust the Touch-Up Additive For Aqua Premium -LVM 035 100

A3- with 10 % Aqua Premium Hardener -LVM 045 000 A1-. |

|

|

|

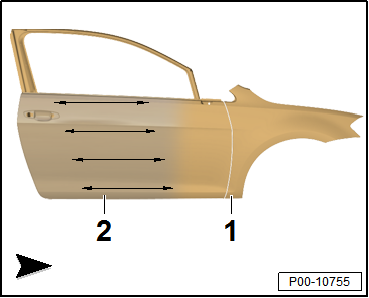

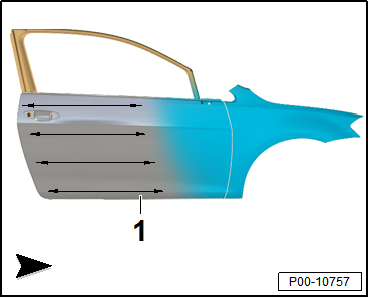

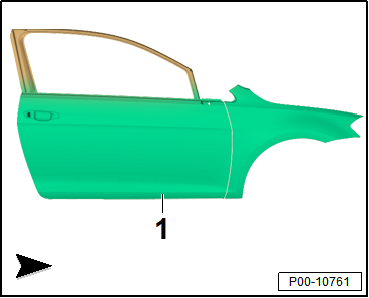

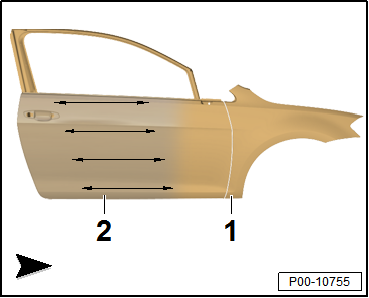

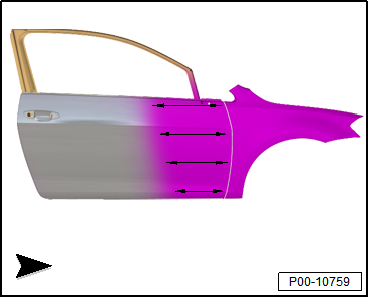

| Repair Process, Touch-up the Neighboring Surfaces (for

Example Color Matching Fender/Door) |

|

|

|

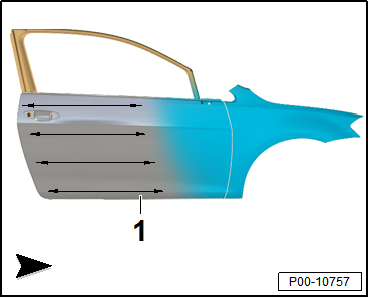

| – |

Apply 1-2 preliminary spray applications of the Touch-Up

Additive For Aqua Premium -LVM 035 100 A3--2-

in the blended area with normal spray pressure on the old

paint/filled surface -1-. |

Note Note

| Pay attention that the blended area is large enough. |

|

|

|

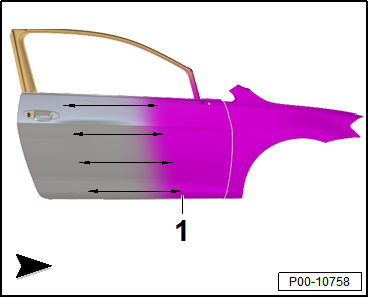

| Adjusting the base color: |

|

|

|

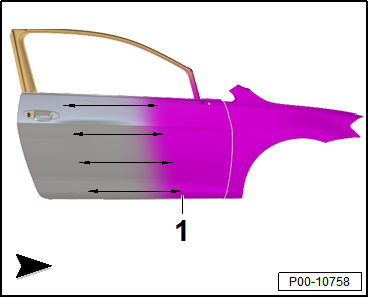

| – |

Apply the primary color shade, adjusted for the 5 % Aqua

Premium Hardener -LVM 045 000 A1- and 10 % Additive For Aqua

Premium -LVM 035 301 A3- for solid colors or 20 % Additive For

Aqua Premium -LVM 035 301 A3- for effect colors and adjusted

base colors -2-, onto the repair

area and on the bordering touch-up area up to the covering

capacity. |

| – |

While doing so the place the run-out area in the wet

Touch-Up Additive For Aqua Premium -LVM 035 100 A3--1-. |

Note Note

| For large surfaces, at high temperatures as well as low

humidity an addition of up to 10 % Aquaplus Purified Water -LVW

010 000 A5- is possible. |

| Effect color, 45 to 60 minutes at +20 °C (68°F) |

| Solid colors, 90 to 120 minutes at +20 °C (68°F) |

|

|

|

| The ventilation time should take place assisted with blowing

devices at 20-40 °C (68°-104°F) until the surface becomes

completely matted. |

| Allow 5 to 10 minutes of intermediate drying time then 10 to

15 minute final drying time at 60° to 65 °C (140° to 149°F). Let

the base color shade cool off before applying the effect. |

| Ventilate until the surface becomes completely matted,

without blowing. |

|

|

|

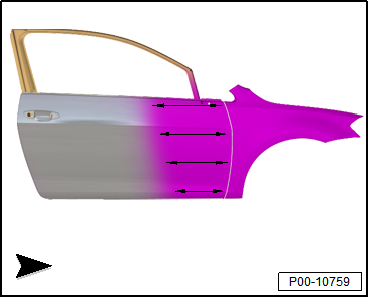

| – |

After ventilating apply 1 to 2 preliminary spray

applications of the Touch-Up Additive For Aqua Premium -LVM 035

100 A3--1- in the blended area

without hardener. |

|

|

|

| Adjusting the effect color: |

| – |

The effect color is adjusted with 20 % Additive for Aqua

Premium - LVM 035 301 A3-. |

Note Note

| For large surfaces, at high temperatures as well as low

humidity an addition of up to 10 % Aquaplus Purified Water -LVW

010 000 A5- is possible. |

|

|

|

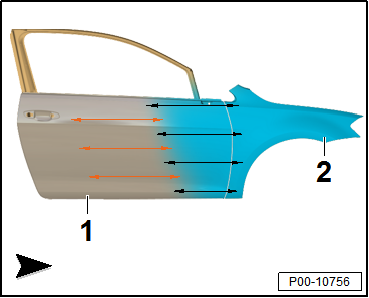

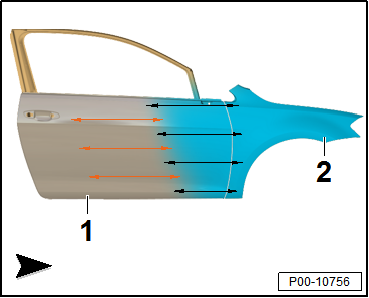

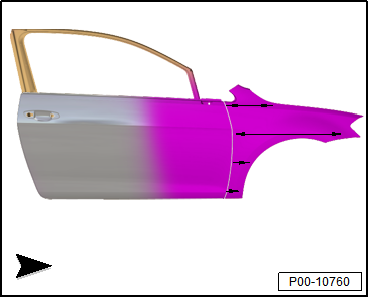

| Step 1, Painting the Effect Color (from the Outside Inward) |

| – |

Apply the effect color from run-out area to the to the new

part -1-. This means it is applied

from the outside toward the inside (»wet-in-wet«)

in the Touch-Up Additive For Aqua Premium -LVM 035 100 A3-. |

| – |

Then if necessary apply the next effect color layer in the

direction of the new part. |

Note Note

| For some effect colors 2 to 3 additional spray applications

are necessary to match the effect. |

|

|

|

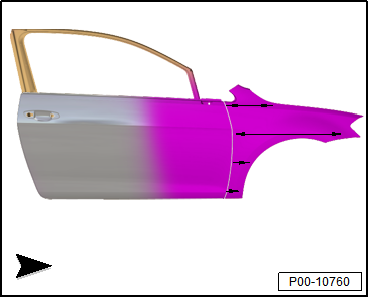

| Step 2, Painting the Effect Color (from the Outside Inward) |

|

|

|

| Step 3, Painting the Effect Color (from the Outside Inward) |

|

|

|

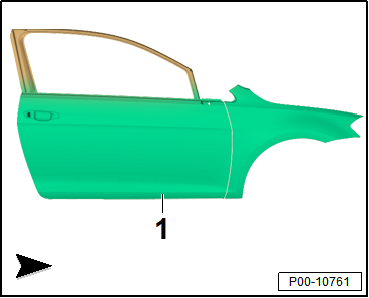

| – |

After ventilating, apply a two-part HS clear coat

-1- over the entire repair surface. |

Note Note

| Starting with the first spray application, it is recommended

to even out the subsequent repair area/base color spray

applications starting from the touch-up area that is farthest

out. For that reason, the subsequent spray applications should

always be remain inside the previous spray application, in order

to avoid visible contours/shadows. |

| While processing the Aqua premium water-based base paint,

the material flow (spray gun trigger) remains completely open. |

| The spraying pressure for the effect spray application can

vary between 1.5 and 2.0 bar depending on the size of the

object. |

| For additional notes to the drying times refer to the

technical application information. |

| Notes for Large Area Applications: |

| Use the Additive for Aqua Premium -LVM 035 301 A3- when

applying 3 coat effect colors. |

| The addition of up to 10 % Aquaplus Purified Water -LVW 010

000 A5- is recommended for large surfaces, high temperatures and

low humidity. |

| For efficient ventilating and drying, stationary blowing

devices or forced drying (for example heated drying) are

recommended. |

| The spray devices should be suitable for use with

water-soluble products; see manufacturer's information. |

| The Aqua Premium mixing paints can only be used within the

color tone formulas. |

| When processing individual mixing paints on their own, major

deviations from the information given in the application

instructions are possible. |

| Rinse before and after using with Aquaplus Purified Water -LVW

010 000 A5-. Then rinse with Nitrocellulose Thinner -LVE 856 000

A3-. |

| Collect liquid waste from water-soluble products and

separate from liquid waste from conventional products. When

mixing materials, disposal may no longer be possible, which is

difficult and costly. |

|

|

|

| Personal Protective Equipment: |

| Note the safety data sheets |

| Wear the personal protective equipment during application |

|

|

|

Edition 04/2013

Product Description/Objective

To achieve an optically flawless color shade transition in

the blended area or a ...

In order to achieve error-free design and multi-colored

paint applications using Aquaplus solid, metallic, pearlescent

base paint, pay attention to the important note ...

Other materials:

CAN Bus Wires, Repairing

Unshielded two-strand wiring -1-

and -2- with a cross section of

0.35 mm2 or 0.5 mm2

can be used as CAN bus wiring.

The color coding of CAN bus wires can be found in the

following table:

...

Indicator lamp

First read and observe the introductory information

and safety warnings

Lit up

Possible cause

Cruise control system (CCS) is controlling the speed.

Several warning and indicator lamps will light up briefly as a functional check

whe ...

Symbols in the roof

Symbol

Meaning

Interior lights and reading lights

Electric panorama sliding/tilting glass roof

...

© 2016-2025 Copyright www.vwpolo.net

Note

Note Note

Note Note

Note Note

Note Note

Note Note

Note Aqua Premium System, Touch-Up System for Two Layer Colors

Aqua Premium System, Touch-Up System for Two Layer Colors Aquaplus Design and Multi-Color Paintwork

Aquaplus Design and Multi-Color Paintwork