Volkswagen Polo Service & Repair Manual: Wires with Cross Section up to 0.35 mm 2,

Repairing

| Special tools and workshop equipment

required |

| Crimping Pliers - .35-2.5mm -VAS1978/1A- |

| Wiring Harness Repair - Crimping Head - .35-2.5mm

-VAS1978/1-1- |

| When repairing wires with a cross-section up to 0.35 mm2,

new contacts must always be crimped on using the Crimping Pliers

- JPT -VAS1978/9A- or the Wiring Harness Repair - Crimping Plier

- Base Tool -VAS1978/1-2- with the Wiring Harness Repair Set -

Crimping Head - JPT -VAS1978/9-1- installed. Due to the low

current strengths of these wires in the micro- to milli- range,

contacts crimped on incorrectly lead to continuity resistances

and cause malfunctions or failure of the respective system. The

most frequent applications of these contacts are |

| By using the Crimping Pliers - JPT -VAS1978/9A- or the

Wiring Harness Repair - Crimping Plier - Base Tool -VAS1978/1-2-

with the Wiring Harness Repair Set - Crimping Head - JPT

-VAS1978/9-1- installed, the correct connection between crimp

contact, wire and single wire seal is guaranteed. The tool is to

be used only for the purpose described. |

Note Note

| Contacts in a normal and a gold-plated version are crimped

onto repair wires. The same version of the contact that was

installed at the factory must always be used for repairs. |

| Crimping A New Contact with Single Wire Seal |

| – |

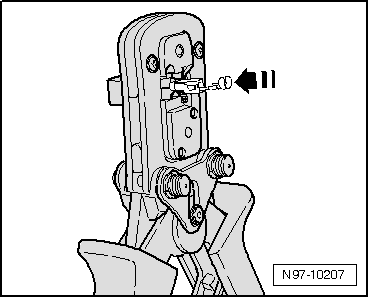

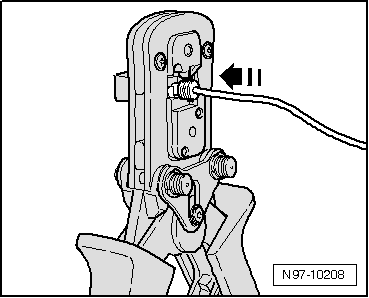

Insert the Wiring Harness Repair Set - Crimping Head - JPT

-VAS1978/9-1- into the Wiring Harness Repair - Crimping Plier -

Base Tool -VAS1978/1-2-. Refer to

→ Chapter „Crimping Pliers - .35-2.5mm -VAS1978/1A-“. |

|

|

|

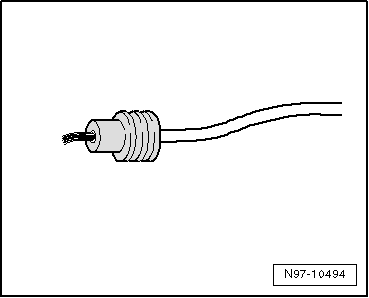

| – |

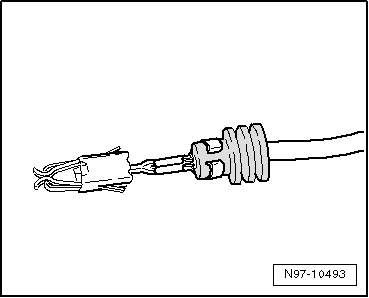

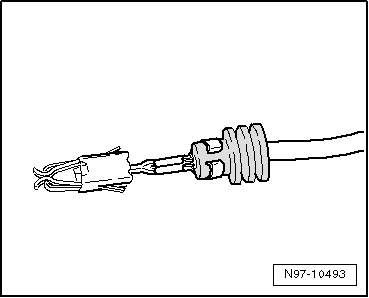

Place the single wire seal onto the repair wire. |

Note Note

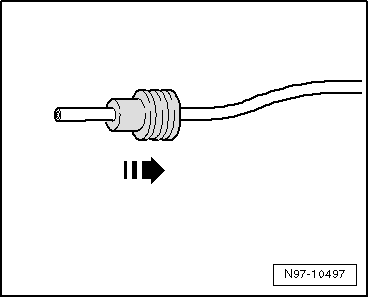

| When doing this, the smaller diameter of single wire seal

must be facing in the direction of the contact to be crimped on. |

|

|

|

| – |

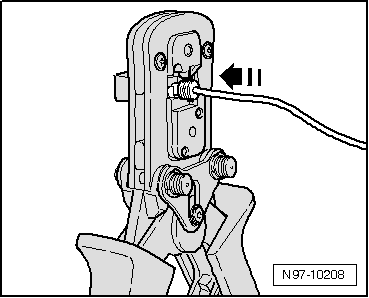

Open crimp pliers and place the repair wire end into

stripping slot of crimp pliers. |

|

|

|

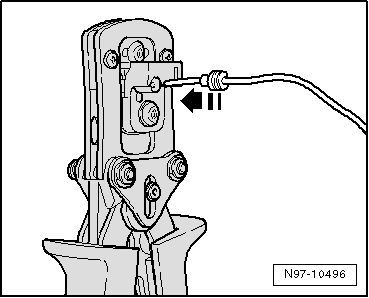

| – |

Close crimp pliers completely. |

| – |

Open crimp pliers again and remove the stripped wire end. |

|

|

|

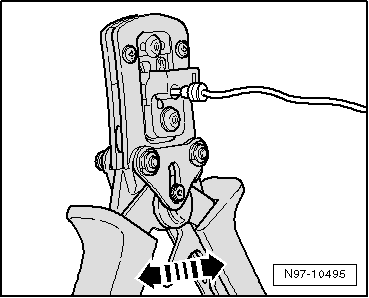

| – |

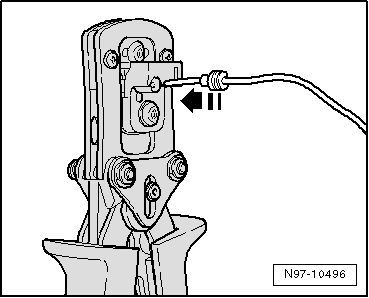

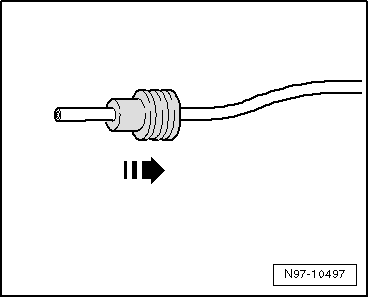

Slide single wire seal in direction of stripped wire end

until it rests flush with the wire insulation. |

|

|

|

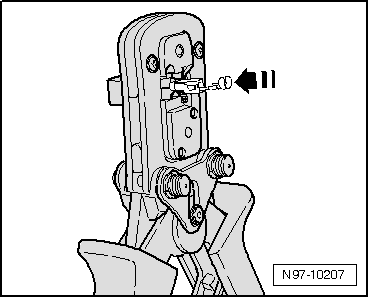

| – |

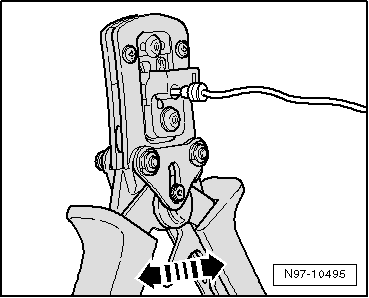

Place new crimp contact into mount on crimp pliers. |

|

|

|

| – |

Insert the stripped wire end with positioned single wire

seal into crimp contact until it makes contact on “wire stop”. |

| – |

Crimp the contact, wire and single wire seal by closing

crimp pliers completely. |

| – |

Open crimp pliers again and remove the finished crimped-on

contact. |

|

|

|

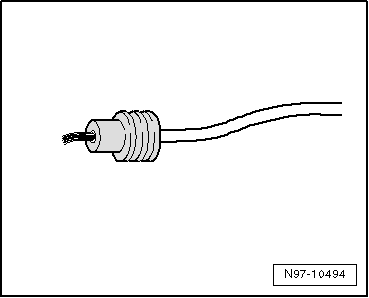

| A correctly performed crimp is distinguished by a clean

compression of wire and single wire seal in the contact and has

an impression on the rear side which identifies that the crimp

was performed by a professional using the correct tool. |

|

|

|

A new repair concept has been developed for repairing

antenna wires. Refer to

→ Chapter „Antenna Wires, Repairing“.

Instead of a ...

Repair point with single crimp connection

–

Free up wire intended for repair (approximately 20 cm to

both sides of repair point).

...

Other materials:

Introduction

This chapter contains information on the following subjects:

→ Indicator lamp

→ Windscreen wiper lever

→ Windscreen wiper functions

→ Service position for the front windscreen wipers

→ Rain/light sensor

→ Checking and refilling the windscree ...

Exterior Lights, Switches

HID Headlamp Usage and Safety Precautions

Special tools and workshop equipment

required

Protective Eyewear

Gloves

–

Note the following if working with HID headlamps:

...

General Information

The following descriptions also apply to Left Rear Cigarette

Lighter -U3-, Right Rear Cigarette Lighter -U7-, Rear Cigarette

Lighter -U9-, 12 V Socket 2 -U18-, 12 V Socket 3 -U19-, 12 V

Socket 4 -U20-, Cigarette Lighter 2 -U25- and 12 V Socket 5

-U26- if ...

© 2016-2025 Copyright www.vwpolo.net

Note

Note Note

Note Antenna Wires, Replacing

Antenna Wires, Replacing Wire Break with Single Repair Point

Wire Break with Single Repair Point