Volkswagen Polo Service & Repair Manual: Wire Break with Single Repair Point

| Repair point with single crimp connection |

| – |

Free up wire intended for repair (approximately 20 cm to

both sides of repair point). |

| – |

If required, remove wiring harness wrapping using a folding

knife. |

|

|

|

| – |

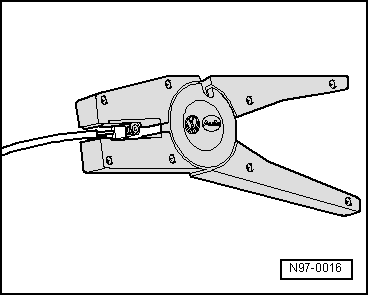

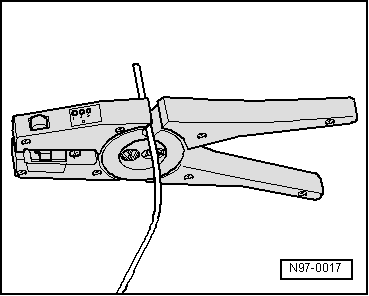

Cut out the damaged section of wire using the Wiring Harness

Repair Set - Wire Strippers -VAS1978/3-. |

Note Note

| If, by cutting out the damaged wire section, both ends of

the vehicle-specific single wire are too short for a repair

using a single crimp connection, insert a repair wire section of

matching length with two crimp connections. Refer to

→ Chapter „Wire Break with Dual Repair Point“. |

|

|

|

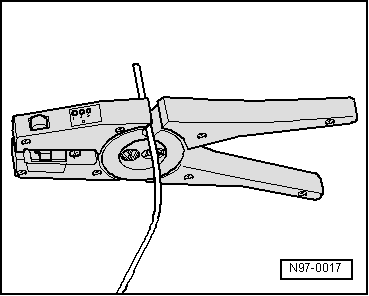

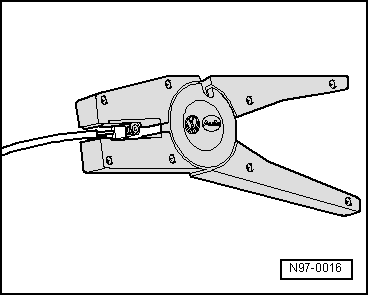

| – |

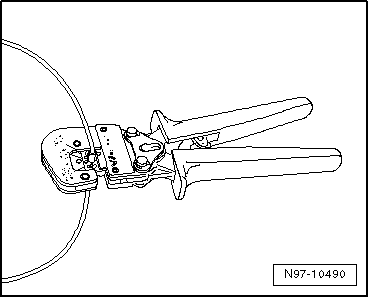

Strip the wire ends using the 6 - 7 mm wire stripper. |

|

|

|

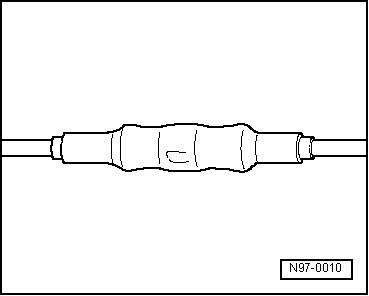

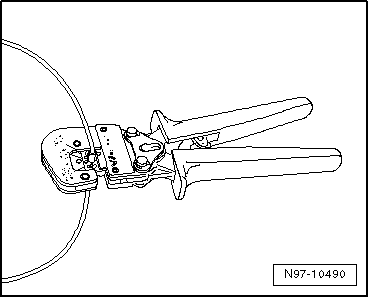

| – |

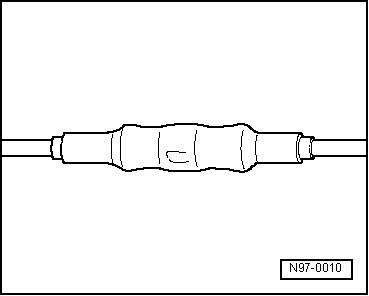

Slide crimp connection onto both stripped wire ends of

vehicle-specific single wire and crimp them using crimp pliers. |

Note Note

| Always be sure to use the correct crimping slot for the

crimping connection used. Refer to

→ Chapter „Crimping Pliers with Insert“. |

| Do not crimp wire insulation. |

| After crimping, crimp connections must be heat-shrunk using

hot air gun to prevent moisture penetration. |

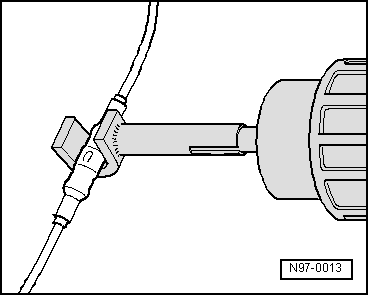

| – |

Place the Wiring Harness Repair - Blower - Shrink Element

-VAS1978/15A- on the Wiring Harness Repair Set - Hot Air Blower

-VAS1978/14A-. |

|

|

|

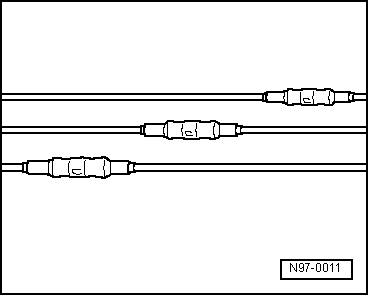

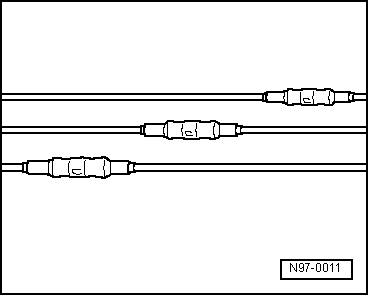

| Make sure that crimp connections do not lie directly next to

each other when several wires need to be repaired. Arrange the

crimp connectors at a slight offset so that the circumference of

the wiring harness does not become too large. |

| In the event the repair point was previous taped, this point

must be taped anew with yellow insulating tape after repairs. |

| Secure the repaired wiring harness if necessary with a cable

tie to prevent flapping noises while driving. |

|

|

|

Special tools and workshop equipment

required

Crimping Pliers - .35-2.5mm -VAS1978/1A-

Wiring Harness Repair - Cri ...

Repair point with intermediate wire section

–

Free up wire intended for repair at two points

(approximately 20 cm to both sides of resp ...

Other materials:

Stowage

Fig. 161 In the luggage

compartment underneath the floor covering A: Spare wheel and vehicle toolkit

without ball coupling, B: Spare wheel and vehicle toolkit with ball coupling, C:

Spare wheel and vehicle toolkit without ball coupling

First read and observe the introductory

information an ...

Support Mode with Battery Charger -VAS5900

General Information

The support mode provides the vehicle electrical system with

voltage when the battery is removed or disconnected.

For more information. Refer to Battery Charger -VAS5900-

Operating Instructions.

...

Front view

Fig. 2 Overview of the front of the

vehicle

Key for :

Rain/light sensor on the mirror base

Windscreen

Windscreen wiper

Bonnet

Bonnet release lever

Headlights

Headlight washer system

Mounting for the front towing eye behind

a cover

Front number plate holder

F ...

© 2016-2026 Copyright www.vwpolo.net

Note

Note Note

Note Note

Note Wires with Cross Section up to 0.35 mm 2,

Repairing

Wires with Cross Section up to 0.35 mm 2,

Repairing Wire Break with Dual Repair Point

Wire Break with Dual Repair Point

Caution

Caution