Volkswagen Polo Owners Manual: Wheel bolts

Fig. 166 Changing a wheel: loosening the wheel bolts

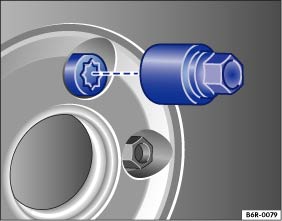

Fig. 167 Changing a wheel: anti-theft bolt and adapter

First read and observe the introductory

information and safety warnings

First read and observe the introductory

information and safety warnings

Only the spanner delivered with the vehicle should be used to loosen the wheel bolts.

Only loosen the wheel bolts by approximately one turn before raising the vehicle with the vehicle jack.

If the wheel bolt is very tight, you may be able to loosen it by pushing down the end of the spanner carefully with your foot. Hold on to the car for support and take care not to slip.

Loosening the wheel bolts

- Fit the box spanner over the wheel bolt as far as it will go .

- Hold the end of the box spanner and turn the wheel bolt one turn anticlockwise .

Loosening the anti-theft wheel bolt

- Take the adapter for anti-theft wheel bolts out of the vehicle toolkit.

- Insert the adapter into the anti-theft wheel bolt . Push it in as far as it will go.

- Insert the box spanner into the adapter as far as it will go.

- Hold the end of the box spanner and turn the wheel bolt one turn anticlockwise .

Important information about the wheel bolts

The design of the wheel rims and wheel bolts is matched to the factory-fitted wheels. If different rims are fitted, the correct wheel bolts with the right length and correctly shaped bolt heads must be used. This ensures that wheels are fitted securely and that the brake system works properly.

In certain circumstances, wheel bolts from a vehicle of the same model series may not be used.

Tightening torque for the wheel bolts

The tightening torque for wheel bolts for steel and alloy wheels is 120 Nm. The tightening torque should be checked with a torque wrench immediately after changing a wheel.

If the wheel bolts are corroded and difficult to turn, they must be replaced and the wheel hub threads cleaned before the tightening torque is checked.

Never grease or lubricate the wheel bolts or the threads of the wheel hub. This could cause them to loosen while the vehicle is in motion, even if the required torque setting is used.

WARNING

WARNING

- Only use wheel bolts that belong to the wheel.

- Never use different wheel bolts.

- The wheel bolts and threads of the wheel hubs must be clean, free from oil and grease, and turn easily.

- Always use the box spanner placed in the vehicle at the factory to loosen and tighten the wheel bolts.

- Only loosen the wheel bolts by approximately one turn before raising the vehicle with the vehicle jack.

- Never grease or lubricate the wheel bolts or the threads of the wheel hub. This could cause them to loosen while the vehicle is in motion, even if the required torque setting is used.

- Never remove the bolts on rims with bolted-on rings.

- If the tightening torque of the wheel bolts is too low, the wheel bolts and rims can loosen while the vehicle is in motion. The wheel bolts and threads can be damaged if the tightening torque is too high.

Checklist

Checklist

The following actions must always be carried out in the given

order in preparation for changing the wheel :

In the event of a flat tyre, park

your vehicle on a firm and level surface at a s ...

Lifting the vehicle with the jack

Lifting the vehicle with the jack

Fig. 168 Jacking points for the

vehicle jack (mirrored on the right-hand side of the vehicle)

Fig. 169 Vehicle jack at the rear

left-hand side of the vehicle

First read and observe the introdu ...

Other materials:

Battery Terminal Clamp and Battery Terminal, Cleaning

Special tools and workshop equipment

required

Torque Wrench 1331 5-50Nm -VAG1331-

The Contact Surface Cleaning Set -VAS6410- makes optimal

repair quality possible in the realm of vehicle electronics.

Using th ...

Long-Term Underbody Protection -D 314 D38 M2-, Bright Color

Definition:

Long-Term Underbody Protection -D 314 D38 M2-, Bright Color

Edition 02/2010

Product Description

Long-Term Underbody Protection -D 314 D38 M2- is a bright,

transpa ...

Laws and Regulations

Note

The laws and regulations listed below are applicable in

Germany. Different or additional laws and regulations may apply

in other countries.

Addresses in other countries can be obtained from the

relevant au ...