Volkswagen Polo Service & Repair Manual: Wheel, Balancing on Stationary Balancing Machine

| Before beginning balancing, the following requirements must

be fulfilled. |

| The tire pressure must be OK. |

| The tire profile must not be worn on one side. The tire

profile must be at least 4 mm. |

| The tires must not have any damage such as cuts, holes,

foreign bodies, etc. |

| The suspension and steering, including the shock absorber,

must be in perfect condition. |

| Test drive performed. Refer to

→ Chapter „Vibration, Road Test, Performing Before Balancing“. |

Note Note

| If equipped handle the glued-on wheel trim carefully.

Surface slightly scratched. |

| Replace the damaged rim wheel trim. |

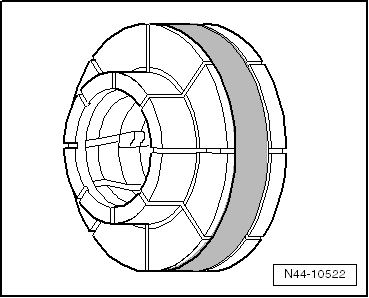

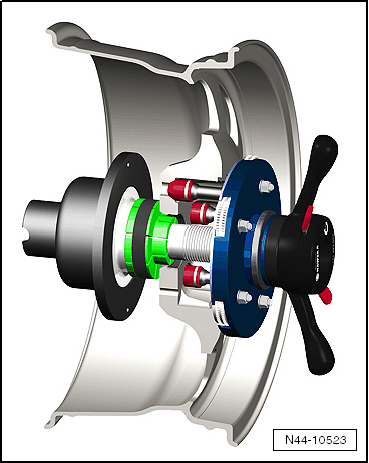

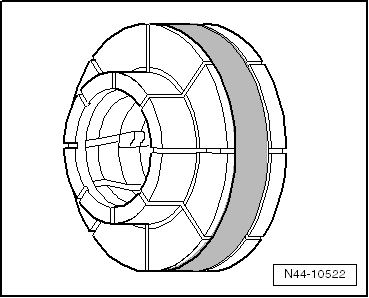

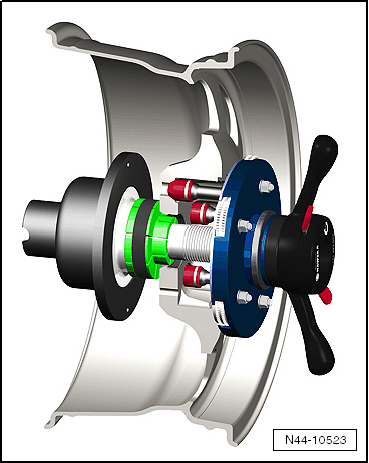

| Use only the Model-Specific Clamping Plate VAS6652 -VAS6652-

and the Thrust Pin -VAS6652/1-. |

| Tension Wheel on Balancing Machine |

| Dirt and rust in the area of the contact surfaces and

centering of the wheel distort the result. |

| – |

Clean contact surfaces, centering seat and wheel disc using

the Pneumatic Brush Grinder Set -VAS6446- before tensioning

wheel on balancing machine! Refer to Workshop Equipment,

Catalog. |

Note Note

| The wheel balancing machine must use the correct system for

centering and tensioning the tires when replacing them Reference

the information for the Wheel Balancing Machine Centering System

before beginning any work. Refer to Workshop Equipment, Catalog. |

|

|

|

| – |

Tension the wheel with the tire on the balancing machine. |

Note Note

|

|

|

| To mount wheel on wheel balancer, use for example Wheel

Centering System Adapter -VAS5271-. |

| This way a 100% centering of the wheel and gentle mounting

is possible! |

| It is not possible to center it 100% on balancing machine

with conical tensioners. |

| With a deviation of 0.1 mm outside the center, there is an

imbalance of 10 grams on the wheel/tire. |

| Wheel/Tire Balancing Procedure |

| – |

Let the wheel/tire turn on the balancing machine. |

| – |

Check the run of the characteristic lines on the sidewall of

the tire in the area of the rim flange. |

| – |

Check the tire wear pattern while the wheel/tire is turning. |

Note Note

| In the event of one-sided wear, flat spots from braking or

severe wear spots, smooth running cannot be achieved by

balancing. In this case, the tire must be replaced. |

| – |

Check the run-out on the wheel/tire. If the wheel with tire

runs untrue although there are no flat spots, a radial or

lateral run-out may be the cause. |

| – |

Check wheel with tire for radial- and lateral run-out. Refer

to

→ Chapter „Wheel, Balancing, Tire and Wheel Radial and Lateral

Run-Out, Checking“. |

| – |

If the radial and lateral run-out are within the specified

tolerance, balance the wheel and tire. |

Note Note

| Do not use more than 60 grams of weight per wheel. |

| If more weight is necessary, a smoother running can achieved

by matched mounting of the tire. Matching a tire. Refer to

→ Chapter „Tires and Rims, Matching“. |

| The display in the balancing machine should show 0 grams. |

| Hunter RFT33VAG Road Force Touch™ Wheel Balancer -VAS6230B4-

can be inserted as an alternative to matching. Refer to

→ Chapter „Vibration, Vibration Control System“. |

| – |

Install the wheel on the vehicle. |

Caution

Caution

| If brake pads are ceramics, wheel must not fall on

brake rotor, otherwise it will be destroyed. To

remove/install wheel, install long assembly pin instead

of wheel bolts in top position (12:00 position) and

short assembly pin in wheel bolt mounts for support. In

this way, the wheel can glide on the assembly aids when

removing/installing. |

|

| – |

Tighten the lowest wheel bolt by hand to approximately 30

Nm. |

| – |

Tighten the remaining wheel bolts diagonally to

approximately 30 Nm. This process centers the wheel on the wheel

hub. |

| – |

Lower the vehicle onto its wheels. |

| – |

Use a torque wrench to tighten the wheel bolts diagonally to

the specified tightening specification. |

| If a vibration is still detected during the road test, the

cause may be due to tolerance in the wheel centering. |

| The component tolerances of wheels and wheel hubs can be

additive in unfavorable cases. Vibration can result from this.

This can be eliminated using a finish balancer. Refer to

→ Chapter „Wheel, Balancing with Fine Balancing Machine (Finish

Balancer)“. |

|

|

|

Before beginning balancing, the following requirements must

be fulfilled.

The tire pressure must be OK.

The tire p ...

Other materials:

Fiber-Optic Cable, Assembling

Special tools and workshop equipment

required

Fiber-Optic Conductor Repair Set -VAS6223A-

Hose Cutting Pliers -VAS6228-

Vehicle Diagnostic Tester

It is very diffi ...

Safety Precautions

General Safety Precautions

As per VBG 20, German industrial liability insurance

association.

Follow the instructions for the workplace. They should be

displayed in the workplace.

...

Tyre Pressure Loss Indicator

Fig. 124 In the stowage compartment on

the front passenger side: button for the Tyre Pressure Loss Indicator

First read and observe the introductory information

and safety warnings The Tyre Pressure Loss Indicator uses data

from the ABS sensors and other functions to check the speed of rot ...

© 2016-2026 Copyright www.vwpolo.net

Note

Note Note

Note Note

Note Note

Note Note

Note Wheel, Balancing

Wheel, Balancing Wheel, Balancing with Fine Balancing Machine (Finish Balancer)

Wheel, Balancing with Fine Balancing Machine (Finish Balancer)

Caution

Caution