Volkswagen Polo Service & Repair Manual: Fold Corrosion Servicing Notes

| Corrosion on the Fold Edges, for Instance on the Hood, Door

or also the Rear Lid |

| – |

Remove the corroded areas with

→ Chapter „Pneumatic Brush Grinder Set -VAS6446-“ or

→ Chapter „Brush Grinder Set -VAS6776-“. |

| – |

Sand the overlapping areas with P360 - P400 sandpaper. |

| – |

Clean the base surface with Silicone Remover. |

| – |

After a corrosion repair and before sealing, insulate the

base surface with Two-Part Wash Primer -LHV 043 000 A2- and then

fill with Two-Part HS Performance Filler. |

| – |

After the filler has dried, the filled area must be dry

sanded with P400- P500. While doing so, make sure to avoid

“sanding through”. Then clean the sanded areas with Silicone

Remover. |

| – |

After the filler has dried and has been sanded, the metal

edges in the fold area must be thinly sealed with a fine seam

sealant. Refer to

→ Chapter „Sealing Materials“. The fine seam sealant

must match the original state. Refer to

→ Paint; Rep. Gr.00. |

Note Note

| When repairing, the seam sealant is to be returned to

replicate stock visual appearance and layer thickness. |

| Sealing seams near attachments to be installed must be

applied smoothly In order to avoid damage and malfunctions. |

| Water drain holes must remain free. |

| All threaded pins and weld nuts with M-threads, as well as

all other pins and contact surfaces for the assembly must be

functional after the sealant application. |

| The sealing material cannot be applied on blank sheet metal,

but rather on filled surfaces. |

| – |

Recreate the subsequent paint system according to the

manufacturer's specifications. |

| – |

Seal the cavities around the fold area with

→ Chapter „Suction Feed Spray Gun -VAG1538-“. Refer

to

→ Chapter „Preservation“. |

Note Note

| Service work is effective only when the fold area can be

sealed airtight from the inside (so that no moisture can get

in). |

|

|

|

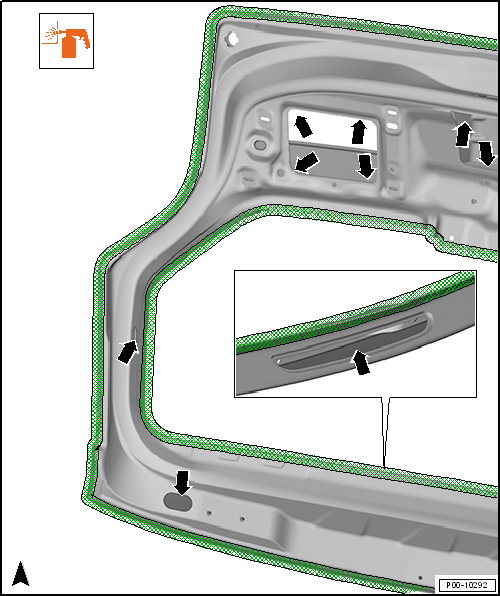

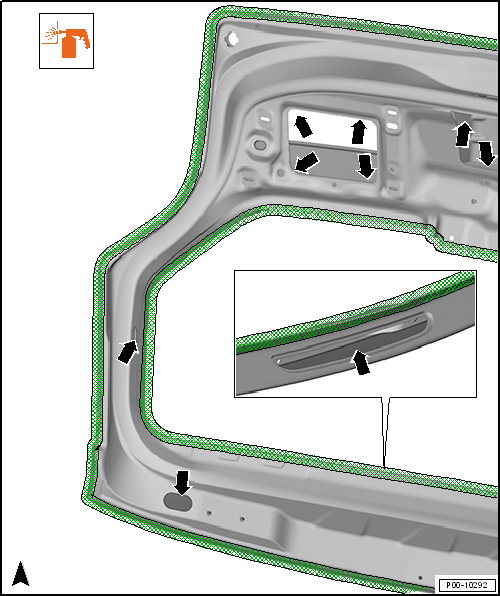

| Cavity Sealant Area Example on Rear Lid |

|

|

|

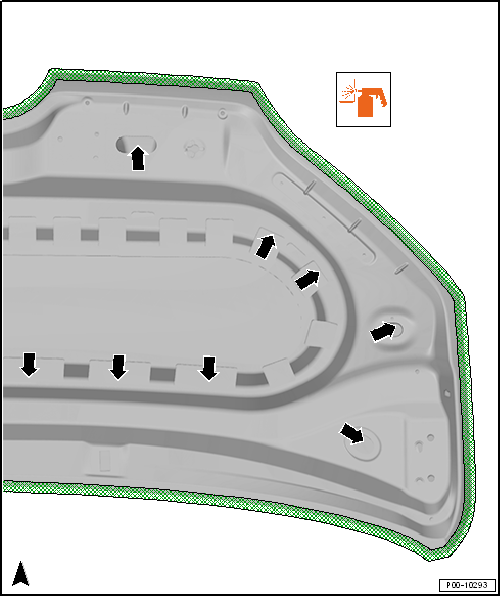

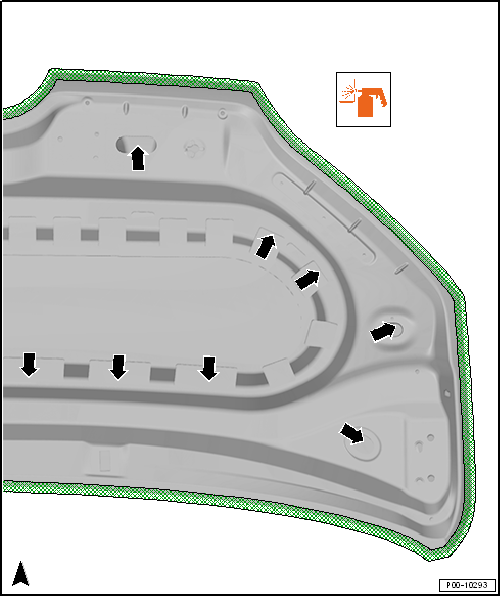

| Cavity Sealant Area Example on Hood |

|

|

|

| Cavity Sealant Area Example on a Door |

|

|

|

Note

The corrosion protection in the fender seam must be applied on all

replacement parts, on which the attached seal is not already present.

The additional ...

Attachments

Coat the insides of the fenders, doors, covers and lids

completely. A spray application wet in wet procedure is

sufficient.

...

Other materials:

Flushing Not Necessary

Note

For vehicles with an electrically-driven A/C compressor,

de-energize the high voltage system before removing the A/C

compressor. Refer to

→ Electrical System Hybrid; Rep. Gr.93.

–

Dischar ...

Odor from Evaporator or Heat Exchanger?

Fishy smell

–

From leak at cooling system of engine or of A/C system

heater core.

Note

If the fishy smell gets weaker when the temperature is set

to “cold” and stronger when i ...

Fastening rings

Fig. 88 In the luggage compartment: fastening

rings

First read and observe the introductory information

and safety warnings

You will find fastening rings at the front and rear of the luggage compartment

which can be used to secure luggage (arrow).

WARNING

Unsuitable or damaged securing s ...

© 2016-2026 Copyright www.vwpolo.net

Note

Note Note

Note Fender Corrosion Repair Measures, in Wheel Housing Liner Contact Area

Fender Corrosion Repair Measures, in Wheel Housing Liner Contact Area Corrosion Protection for Body, Attached and Welded Parts

Corrosion Protection for Body, Attached and Welded Parts