Volkswagen Polo Service & Repair Manual: Bonding Agent

| Bonding Agent -LLS MAX 015-, plastic |

| The Bonding Agent -LLS MAX 015- is a universal

single-component bonding agent for all standard exterior plastic

vehicle parts. |

| All standard plastic parts used on car exteriors (PP, EPDM,

ABS, PC, PPO, PA, R-TPU, PBTP, PVC, PUR, PUR soft foam, UP-GF). |

|

|

|

| Pre-treatment of base surfaces: |

| The base surface must be free of separating agents. |

| Before cleaning plastic parts, temper them for 60 minutes at

+60 ℃ to “sweat out” the separating agents. |

| – |

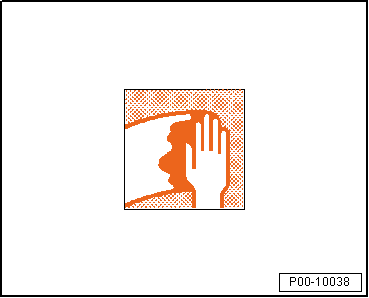

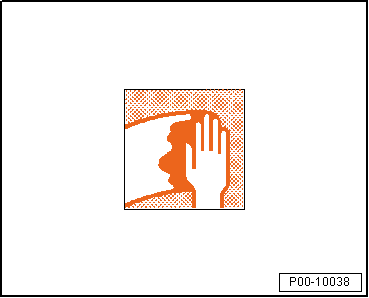

Clean using Antistatic Plastic Cleaner -LVM 001 001 A2- or a

milder Silicone Remover, Long -LVM 020 100 A5-. |

Note Note

| The effort needed for cleaning depends on the type and

quantity of the separating agent used. We recommend using a

sanding pad to help cleaning |

| Let the thinner evaporate (for example, air-drying overnight

at room temperature or 30-40 minutes at +60℃ (140 °F)). |

|

|

|

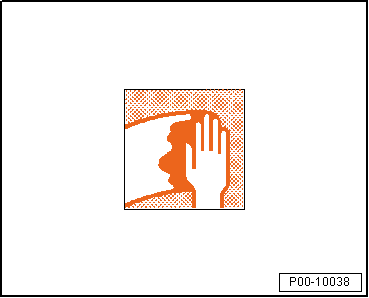

| – |

Before priming, lightly clean again using Antistatic Plastic

Cleaner -LVM 001 001 A2- or Silicone Remover, Long -LVM 020 100

A5- (antistatic effect). |

|

|

|

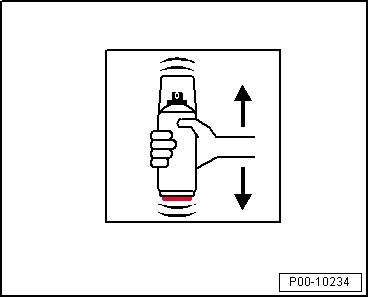

| – |

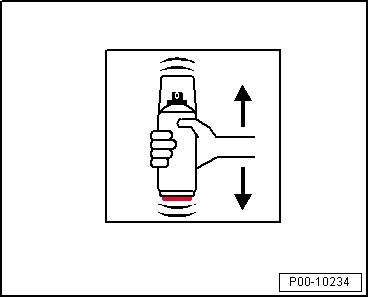

Shake the can thoroughly for two minutes. |

|

|

|

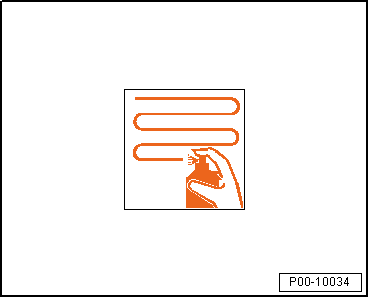

| – |

Apply one preliminary sealed spray application (1-2 µm). |

| – |

Maintain a distance of 20 to 25 cm. |

|

|

|

| VOC value: 2004/42/IIB(e)(840)730 |

The EU limit for this product

(product category IIB.e) in ready-to-use form is a maximum of 840 g/L

volatile organic compounds. The VOC-value of this product in

ready-to-use form is a maximum of 730 g/L. |

| The guaranteed shelf life of 60 months from date of

manufacture. Use no later than the date indicated on the label

and store in original container at +20 °C (68 °F). |

|

|

|

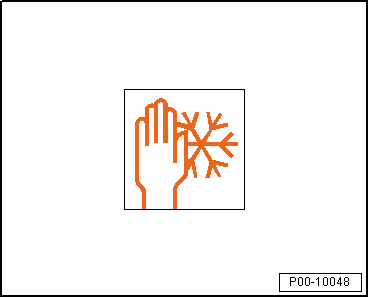

| The prescribed storage temperature is +20 to +25 °C (68 °F

to 77 °F) )(do not to fall below +5 °C (41 °F)). |

|

|

|

Definition:

Blender -LLS MAX 009-

Edition 10/2008

Product Description

The Blende ...

Other materials:

Electric windows – functions

First read and observe the introductory information

and safety warnings

One-touch opening and closing

One-touch opening and closing makes it possible to fully open and close the windows.

The individual buttons do not have to be held down to do this.

For one-touch closing: pull the button for ...

Extraction System Group Classifications

At this time, A/C service units for extracting, cleaning and

filling refrigerant for motor vehicle A/C systems are available

from various manufacturers.

Group 3:

Mobile extraction and charging systems for filling

c ...

Changing gear using Tiptronic

Fig. 113 Selector lever in Tiptronic position

(left-hand drive) The controls are mirrored for right-hand drive vehicles

Fig. 114 Steering wheel with paddles for

Tiptronic

First read and observe the introductory information

and safety warnings Using Tiptronic, the gears can be shifted

u ...

© 2016-2026 Copyright www.vwpolo.net

Note

Note Note

Note Blender

Blender

Caution

Caution