Volkswagen Polo Service & Repair Manual: Wheel, Mounting, Volkswagen Assembly Instructions

| Vehicles With Tire Pressure Monitoring Sensor. |

| If wheels are changed (for example, change from summer to

winter tires), wheel electronics send data as soon as speed of

new wheels exceeds 25 km/h (15.53 mph) The control module

automatically recognizes the identification numbers of the new

wheel electronics. |

| An acceleration data check also occurs with vehicle speed.

This process takes about 7 minutes. |

| Tire Pressure Monitoring Control Module -J502- must first be

in learning mode before it can automatically learn wheel

electronics. |

| Vehicle must stand for 20 minutes for this. This takes 5

minutes after a recognized tire puncture. |

| If the standing time is not followed, control module is not

in learning mode so system recognizes a malfunction and can only

automatically learn wheel electronics after standing 20 minutes. |

Note Note

| When changing wheels, be sure to install only vehicle

manufacturer approved wheel/tires combinations with tire

pressures listed on the tank flap. |

| If unapproved wheel/tire combinations are installed, these

must have a certificate from the technical testing organization

for the particular vehicle and a second wheel set must be

programmed. Refer to Vehicle Diagnostic Tester. |

| An adaptation is also needed if tire pressure deviates from

pressures given on fuel filler flap. |

| Wheel Sets With Other Specified Tire Pressures |

| If a vehicle is equipped with tires which have specified

pressures different from those listed on fuel filler flap, these

tires (second wheel set) can also be monitored by the Tire

Pressure Monitoring System (TPMS). |

| Specified values for a second wheel set must be entered into

the system. Refer to Vehicle Diagnostic Tester. |

| Wheel electronics on wheels from second set are not

automatically recognized and learned by the tire pressure

monitoring system (as wheel electronics on vehicle manufacturer

approved wheel/tire combination set are). |

| To change to a second wheel set, the following steps must be

carried out: |

| Read the wheel electronic (tire pressure sensors)

identification numbers (IDs) before installing. |

| Switch the TPMS to wheel set 2. |

| Enter needed specified tire pressures and wheel electronic

IDs in system. |

| Continuation for All Vehicles |

Note Note

| The wrench size of the included wheel bolt adapter can be

vary from the wrench size of the respective master set. |

| Special tools and workshop equipment

required |

| Torque Wrench 1332 40-200Nm -VAG1332- |

| Wheel Bolt Master Socket Set -T10101- |

| Wheel Bolt Master Socket Set -T10101A- |

| Wheel Bolt Master Socket Set -T40004- |

| Wheel Bolt Master Socket Set -T40073- |

| Optimol AT Paste -G 052 109 A2- |

WARNING

WARNING

| The secure seating of the wheel bolts and the wheels

is only ensured if the instructions and checks below are

followed. |

|

Note Note

| After removing or installing one or multiple tires, the tire

pressure monitoring system must be recalibrated for vehicles

with tire pressure monitoring system. Refer to Vehicle

Diagnostic Tester. |

|

|

|

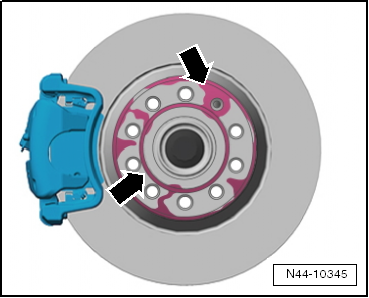

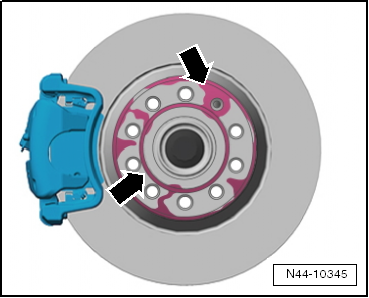

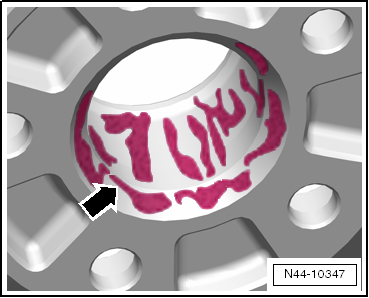

| – |

Make sure the contact surfaces

-arrows- on the brake rotor are free of corrosion and

dirt. |

|

|

|

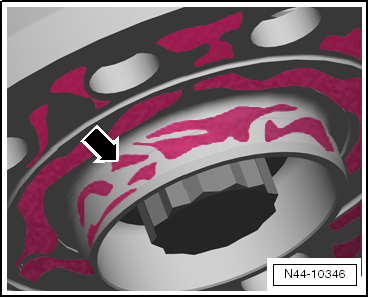

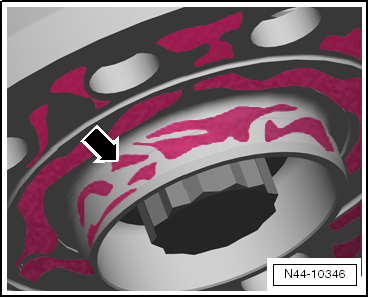

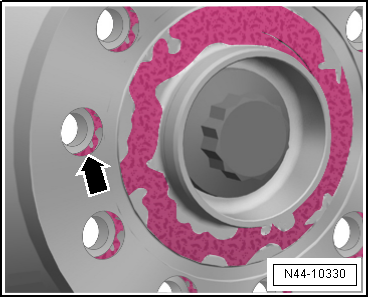

| – |

Make sure the contact surfaces -arrow-

on the brake rotor center seat are free of corrosion and dirt. |

|

|

|

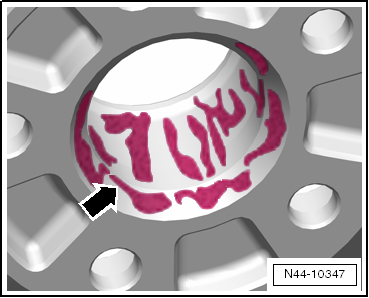

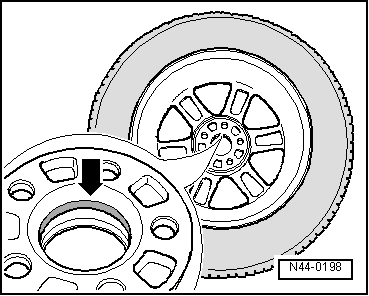

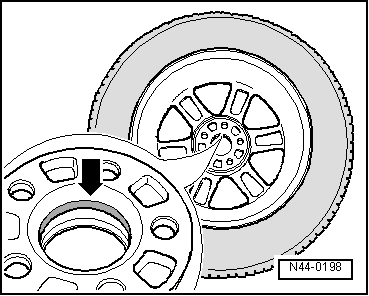

| – |

Make sure the contact surface -arrow-

on the wheel inner side (rim) as well as the central seat in the

rim is free of corrosion and dirt. |

| – |

The spherical caps * in the

wheel bolt openings and the wheel bolt threads must likewise be

free of corrosion, dirt, oil or grease. |

| * The spherical cap is the

curved surface of a section of a sphere. |

|

|

|

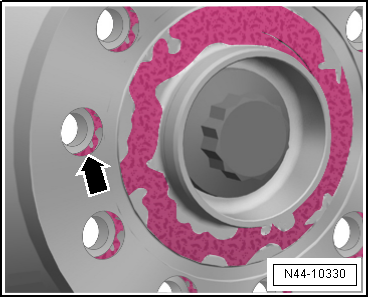

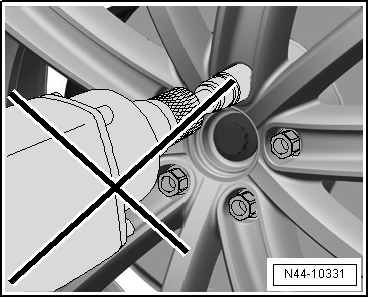

| – |

Check whether the wheel bolts can be easily screwed in by

hand. The threads of the wheel bolts must not touch the holes in

the brake rotor -arrow-. |

| If the thread of the wheel bolt touches the hole

-arrow-, turn the brake rotor

accordingly. |

| Remove Any Dirt or Corrosion if Necessary: |

| Oil or grease from the contact surfaces |

| Oil or grease from the threads on the wheel hub |

| Oil or grease from the threads on the wheel bolts |

WARNING

WARNING

| Heavily corroded, difficult to turn or damaged wheel

bolts must be replaced. |

|

| Applies to Light-Alloy and Steel Wheels |

| When a wheel is changed, the centering seat should be

sprayed with Wax Spray to prevent corrosion between the

centering seat and the wheel rim. Refer to the Parts Catalog. |

| – |

Thoroughly clean the centering seat on the wheel hub and the

centering surface on the rim. |

|

|

|

| – |

Apply wax in area of centering -arrow-

using a brush. |

| Always Make Sure that Only Centering

-arrow- is Waxed and Not Rim Contact Surfaces. As a

Consequence, the Brakes Would Become Contaminated While Driving

and Thereby Result In Poor Braking. |

WARNING

WARNING

| Wheel bolts, contact surfaces of wheel/wheel hub and

the threads in the wheel hubs must not have wax applied

to them. Never apply lubricants or anti-corrosion

treatment to threads in wheel hubs. |

|

| 1 - |

When mounting a wheel, tighten all wheel bolts uniformly by

hand. |

| 2 - |

Tighten the wheel bolts diagonally to approximately 30 Nm. |

| 3 - |

Lower the vehicles onto the floor. Tighten all the wheel

bolts diagonally to the tightening specification using a torque

wrench. |

|

|

|

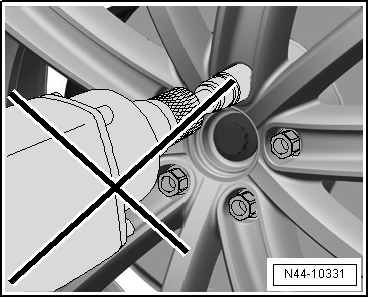

| Do Not Use an Impact Wrench! |

WARNING

WARNING

| Do not use an impact wrench to install the wheel

bolts. |

|

| Refer to

→ Suspension, Wheels, Steering; Rep. Gr.44. |

|

|

|

Vehicles with Tire Pressure Monitoring Sensor.

If wheels are changed (for example, change from summer to

winter tires), wheel electronics send data a ...

© 2016-2025 Copyright www.vwpolo.net

Note

Note Note

Note Note

Note Wheel, Mounting

Wheel, Mounting Wheel, Mounting, Audi Assembly Instructions

Wheel, Mounting, Audi Assembly Instructions

WARNING

WARNING