Volkswagen Polo Service & Repair Manual: Vehicle Electrical System, General Repair Information

Caution

Caution

| Follow the procedure in the repair manual when

disconnecting and connecting the battery. |

|

WARNING

WARNING

| Some tools are supplied with a tool safety clip,

which is slid over the tool points after using the tool,

in order to protect other workers from injuries and tool

points from damage. |

|

| Observe the current notes in the corresponding repair manual

for all repairs. |

| Observe country-specific regulations. |

| Before working on the electrical system, the battery ground

cable must be disconnected. By disconnecting the battery ground

cable (current disruption), the electrical system is guaranteed

to be safe to work on. Disconnecting the positive battery cable

is only required when removing the battery. |

| Before commencing repair work, always eliminate cause of

damage, for example, sharp body edges, faulty components,

corrosion etc. |

| Further information, for example, installing and removing

the individual components, can be found in the appropriate

Repair Manual. |

|

|

|

| Soldering is not permissible for repairs to the vehicle

electrical system. |

|

|

|

| Repair to the wiring harnesses and connectors on the vehicle

electrical system may only be performed using the Wiring Harness

Repair Set -VAS1978B- and with previous versions. Only use the

yellow wires from the Wiring Harness Repair Set -VAS1978B-. |

| Wiring harness repairs may not be performed again in the

wrapping of the vehicle-specific wiring harness and are to be

marked with yellow adhesive tape. This indicated a previous

repair. |

|

|

|

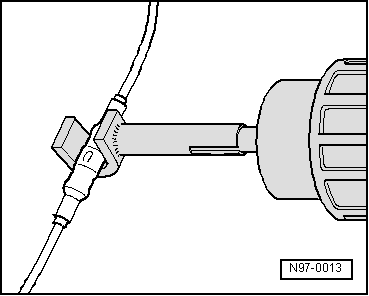

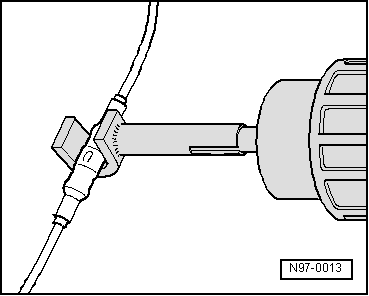

| Crimp connections must never be repaired. If necessary, lay

a wire parallel to the faulty wire. After crimping, crimp

connections must be heat-shrunk using hot air gun to prevent

moisture penetration. |

| Always observe also the supplementary notes for repairing

wiring harnesses on airbag- and seat belt tensioner systems,

fiber optic cables, CAN-Bus wires, antenna wires and wire

cross-sections up to 0.35 mm2. Refer

to

→ Chapter „Wires with Cross Section up to 0.35 mm

2, Repairing“. |

| A function test must be performed after every repair. If

necessary, check DTC memory, erase and/or bring systems into

basic setting. |

|

|

|

| If possible, do not loosen grounding straps from the body

(danger of corrosion). |

|

|

|

| Not all wire cross-sections in the vehicle are contained in

the Wiring Harness Repair Set -VAS1978B- and its previous

versions. If the required wire cross-section is not present, the

next greater cross-section must be used. |

| Shielded harnesses may be repaired. Camera system wires are

the exception. If faulty, the entire harness must be replaced. |

| Heat-resistant wires have been installed in the vehicle at

various locations, mainly in the engine compartment.

Heat-resistant wires can be recognized by their somewhat duller

and softer insulation. Only heat-resistant wires may be used to

repair these wires. |

|

|

|

Other materials:

Paint Thickness Tester -VAS6272

Definition:

Paint Thickness Tester -VAS6272-

Product Description

The paint layer thickness measuring instrument -VAS6272

Paint Thickness Tester- is a combination measuring instrument

used for ...

Vehicle lifting points

Fig. 150 Lifting points at front for the

lifting platform or vehicle jack

Fig. 151 Lifting points at rear for the

lifting platform or vehicle jack

First read and observe the introductory information

and safety warningsThe vehicle may only be lifted at the points shown in

the illustration ...

Retrofitting two-way radios

First read and observe the introductory information

and safety warningsYou will need an external aerial to use a two-way radio

in the vehicle.

Any retrofit installation of electrical or electronic equipment in the vehicle

will affect its vehicle type approval. Under certain circumstances, thi ...

© 2016-2026 Copyright www.vwpolo.net

Caution

Caution WARNING

WARNING