Volkswagen Polo Service & Repair Manual: Two-Part Epoxy Primer Filler

| Two-Part Epoxy Primer Filler -LLS MAX 220 M1-, beige (250

ml) |

| Two-Part Epoxy Primer Filler -LLS MAX 220 M2-, beige (400

ml) |

| The Two-Part Epoxy Primer Filler -LLS MAX 220 M1/M2- is a

two-component epoxy spray can for use with small damaged areas.

Do not use in areas vulnerable to stone impact. |

| The EP primer filler must be protected by the trim panels,

body covers, wheel housing liners and UBS material in the

underbody area. All difficult to reach areas must be sealed with

wax underbody protection. |

| For work safety, wear appropriate, personal protective

equipment. |

| Can be used in a number of ways |

| Good corrosion protection |

| Cleaned and sanded, galvanized/electrolytically zinced sheet

steel or soft aluminum |

| Well-sanded old paint or factory paint |

| Original replacement primer, sanded |

| Cleaned and sanded UP-GF surfaces, free of separating agents |

| Surfaces prepared with two-part polyester products and then

sanded very fine. |

|

|

|

| Pre-treatment of base surfaces: |

| – |

Carefully clean using Silicone Remover -LVM 020 000 A5- or

Silicone Remover, Long -LVM 020 100 A5-. |

|

|

|

| – |

Use a suitable cleaning agent before reworking to ensure a

clean and residue-free surface. |

Caution

Caution

| The Two-Part Epoxy Primer Filler -LLS MAX 220 M1/M2-

may not be applied to PVB (acid-hardening) adhesive

primers or one-part primers (for example, synthetic

resin). |

|

|

|

|

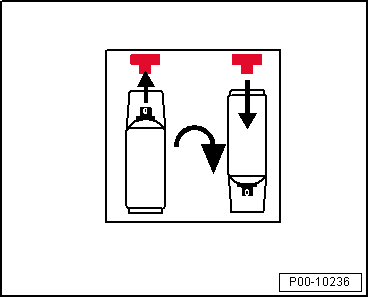

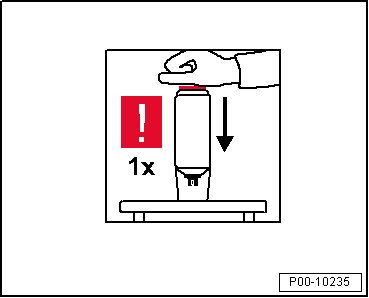

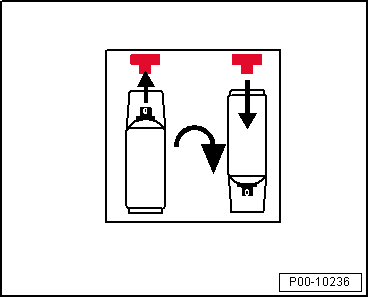

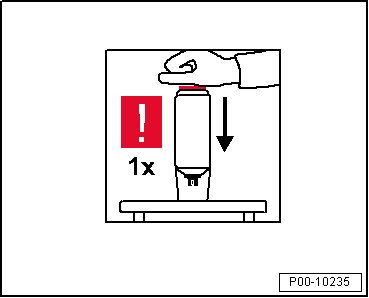

| – |

Remove the red push button on the cap and set it on the

valve for the hardener mixture on the bottom of the can. |

|

|

|

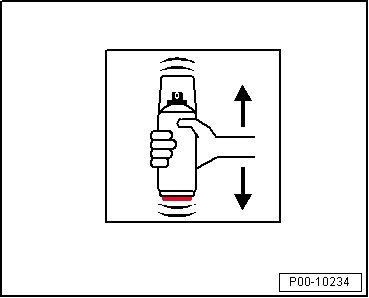

| – |

Press in the valve for the hardener mixture. Make sure when

pressing down the valve for the hardener mixture that the can is

upside down. |

|

|

|

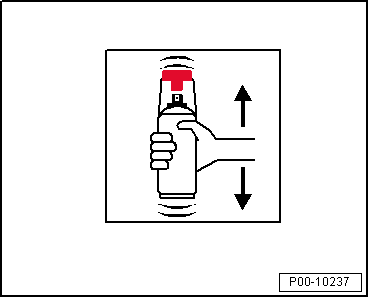

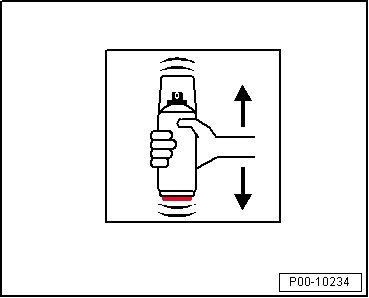

| – |

Shake the can thoroughly for two minutes. |

|

|

|

| Processing time/pot life: |

| – |

Eight hours at +20 °C (68 °F) |

|

|

|

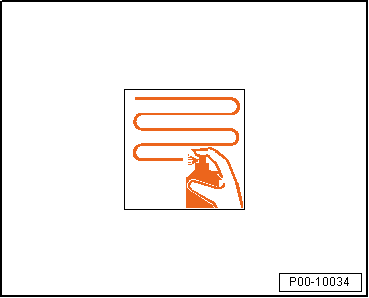

| – |

Apply two to three spray applications with a 5 to 10 minute

intermediate ventilation time. |

| – |

Maintain a distance of 20 to 25 cm. |

| – |

Minimum +15 °C (59 °F). |

| – |

The recommended dry layer thickness is between 50 and 70 µm. |

Note Note

| If the spraying procedure is interrupted, make sure that the

valve above the spray head is empty to prevent any nozzle

blockage. |

|

|

|

| The drying time with forced drying is at least 5 to 15

minutes. |

|

|

|

| Forced drying at +60 to 65 °C (140° to 149 °F) object

temperature is 40 to 45 minutes for a layer thickness of 50 to

70 µm. |

|

|

|

| The drying time for IR drying is a minimum of 10 to 20

minutes. |

|

|

|

| IR drying with a 50 to 70 µm layer thickness is 3 to 5

minutes with a short-wave heater at 50% power and then 15 to 20

minutes at 100% power. |

|

|

|

| – |

Dry-sand with rotary sander and dust extraction. P400-500

grit sandpaper |

|

|

|

| – |

Wet-sand with P800-1000 grit sandpaper |

|

|

|

| VOC value: 2004/42/IIB(e)(840)650 |

The EU limit for this product

(product category IIB.b) in ready-to-use form is a maximum of 840 g/L

volatile organic compounds. The VOC-value of this product in

ready-to-use form is a maximum of 650 g/L. |

| The guaranteed shelf life of 36 months from date of

manufacture. Use no later than the date indicated on the label

and store in original container at +20 °C (68 °F). |

|

|

|

Definition:

Two-Part Clear Coat -LLS MAX 210-

Edition 12/2010

Product Description

...

Definition:

Two-Part Wash Primer -LLS MAX 230 M1-, olive green (250 ml)

Edition 12/2013

Product Descrip ...

Other materials:

Securing mounts, roof bars or load carrying system

Fig. 90 Securing points for mounts or

roof bars (both sides) A: for 2-door vehicles without roof railing. B: for 4-door

vehicles without roof railing. C: for vehicles with roof railing

First read and observe the introductory information

and safety warnings

Mounts or roof bars serve as the b ...

Infrared Dryer -VAS6873

Definition:

Infrared Dryer -VAS6873-

Product Description:

The short-wave infrared dryer is used to quickly dry paste,

filler, base paint, top coats and clear coats for minor repairs.

...

A/C Service Station, Connecting for Measuring and Testing

Caution

If it is suspected that chemicals were added to the

refrigerant circuit to seal leaks, do not connect the

A/C service station and do not extract the refrigerant.

...

© 2016-2025 Copyright www.vwpolo.net

Note

Note Note

Note Two-Part Clear Coat

Two-Part Clear Coat Two-Part Wash Primer

Two-Part Wash Primer

Caution

Caution