Volkswagen Polo Service & Repair Manual: Checking with Restrictor, Reservoir and A/C Compressor Regulator Valve

-N280-, Externally Regulated A/C Compressor

Note Note

| Connecting service station. Refer to

→ Chapter ‚ÄûConnecting Service Station‚Äú. |

| Observe test requirements. Refer to

→ Chapter ‚ÄûPressures, Checking‚Äú. |

| – |

Bring engine speed up to 2000 RPM. |

| – |

Pay attention to the A/C service station pressure gauge. |

Note Note

| Switching pressures for actuation of A/C Compressor

Regulator Valve -N280- and Coolant Fan -V7- are

vehicle-specific. |

| Increasing from initial pressure (when connecting pressure

gauges) to 20 bar (290 psi). |

|

|

|

| Decreasing from initial pressure (when connecting pressure

gauges) to the value in the graph. |

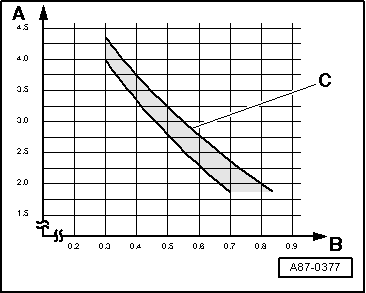

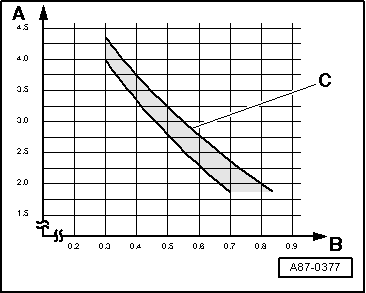

| A - |

Low pressure (measured at service connection) in bar (psi)

absolute |

| B - |

Control current for A/C Compressor Regulator Valve -N280-. |

| C - |

Permissible tolerance range |

Note Note

| Under unfavorable conditions (very high ambient

temperatures, high humidity), pressure on high-pressure side may

increase to max. 29 bar (421 psi).

|

| The control current -B- is

shown in the measured value block. |

| The high pressure is shown in the measured value block.

Refer to

→ Rep. Gr.87. |

| Low pressure settles as a function of control current for

A/C Compressor Regulator Valve -N280- within compressor output

range in tolerance range. |

| Under unfavorable conditions (very high ambient

temperatures, high humidity), compressor output may not always

be sufficient to attain the specified value. |

| The specified operating current for the regulator valve must

be greater than 0.3 A in order to ensure reliable valve

activation. |

| In the setting “maximum cooling output” control current is

regulated to approximately 0.8 A (displayed in measured value

block). Refer to

→ Rep. Gr.87. |

| At absolute pressure, 0 bar/psi corresponds to absolute

vacuum. Normal ambient pressure corresponds to 1 bar (14.5 psi)

absolute pressure. 0 bar/psi pressure corresponds to an absolute

pressure of 1 bar (14.5 psi) on most pressure gauges (indicated

by 1 bar (14.5 psi) below 0 bar/psi). |

|

|

|

|

Possible deviation from specification |

Possible cause of fault |

Corrective

action |

| High pressure remains constant or increases only slightly

(above pressure with engine stopped), |

| Low pressure quickly drops to value in graph or below

|

| Required cooling output is not attained |

|

| Activation of A/C Compressor Regulator Valve -N280- is

faulty. |

| Not enough refrigerant in refrigerant circuit |

|

| – |

Check activation of A/C Compressor Regulator Valve -N280-.

|

| – |

Localize the leak with leak detector and eliminate |

| – |

Charge the refrigerant circuit. |

|

| Low pressure in line with value in graph |

| Required cooling output is not attained |

|

|

|

| Low pressure too low (see graph) |

| Required cooling output is not attained |

| Low pressure too low (see graph) |

| Required cooling output is not attained |

|

|

|

Note Note

| If no malfunction is found with this complaint, flush

(clean) refrigerant circuit with refrigerant R134a. Refer to

→ Chapter ‚ÄûRefrigerant Circuit, Flushing (Cleaning) with

Refrigerant R134a“. If that is not possible in this

workshop, flush the refrigerant circuit with compressed air and

remove moisture with nitrogen. Refer to

→ Chapter ‚ÄûRefrigerant Circuit, Flushing with Compressed Air and

Nitrogen“. |

|

|

|

|

Possible deviation from specification |

Possible cause of fault |

Corrective

action |

| High pressure only increases slightly above pressure with

engine stopped |

| Low pressure drops only slightly |

| Required cooling output is not attained |

|

| Activation of A/C Compressor Regulator Valve -N280- is

faulty. |

|

| – |

Check activation of A/C Compressor Regulator Valve -N280-. |

| – |

Flush (clean) refrigerant circuit. Refer to

→ Chapter ‚ÄûRefrigerant Circuit, Flushing (Cleaning) with

Refrigerant R134a“. |

| – |

Replace A/C compressor. |

|

| High pressure increases above specification |

| Low pressure drops only slightly |

| Required cooling output is not attained |

|

| Constriction or obstruction in refrigerant circuit |

|

| – |

Run hand over refrigerant circuit to check for differences

in temperature |

| If difference in temperature is found at one component: |

| – |

Replace the hose or pipe if kinked or constricted. |

| – |

In the event of an obstruction, flush refrigerant circuit

with compressed air and nitrogen |

| If no malfunction can be found: |

| – |

Flush (clean) refrigerant circuit. Refer to

→ Chapter ‚ÄûRefrigerant Circuit, Flushing (Cleaning) with

Refrigerant R134a“. |

|

| High and low pressure normal at first, after some time high

pressure increases above specification |

| Low pressure quickly drops to value in graph or below, |

| Required cooling output is no longer attained. |

|

| Moisture in refrigerant circuit |

|

| – |

Flush refrigerant circuit with compressed air and nitrogen. |

| – |

Repeat test if function is not OK. |

| – |

Flush (clean) refrigerant circuit. Refer to

→ Chapter ‚ÄûRefrigerant Circuit, Flushing (Cleaning) with

Refrigerant R134a“. |

| – |

Charge the refrigerant circuit. |

|

| Low pressure too low (see graph) |

| The required cooling performance is obtained |

|

| Activation of A/C Compressor Regulator Valve -N280- is

faulty. |

|

| – |

Check activation of A/C Compressor Regulator Valve -N280-. |

| – |

Flush (clean) refrigerant circuit. Refer to

→ Chapter ‚ÄûRefrigerant Circuit, Flushing (Cleaning) with

Refrigerant R134a“. |

| – |

Replace A/C compressor.

|

|

Note Note

| For the malfunction “high pressure normal, low pressure too

low”, note the following: faulty, the evaporator can ice up or

the cooling output is not reached. |

| With this malfunction, evaporator may ice up although

quantity of refrigerant in circuit is OK. |

| Check measured values of Evaporator Vent Temperature Sensor

-G263- or Evaporator Temperature Sensor -G308-. |

| Check the A/C Compressor Regulator Valve -N280- activation. |

|

|

|

|

Possible deviation from specification |

Possible cause of fault |

Corrective

action |

| High pressure normal or too high |

| Low pressure too high (see graph) |

| A/C compressor noise (particularly after switch-on) |

| Required cooling output is not attained |

|

| Too much refrigerant in the circuit. |

|

| – |

Extract refrigerant from the refrigerant circuit |

| If quantity of refrigerant extracted roughly corresponds to

specified capacity: |

| – |

Replace the A/C compressor. |

| If quantity of refrigerant extracted is substantially

greater than specified capacity: |

| – |

Charge the refrigerant circuit. |

|

| High and low pressure normal |

| Required cooling output is not attained |

|

| To much refrigerant oil in the circuit. |

|

| – |

Discharge the refrigerant circuit. |

| – |

Flush (clean) refrigerant circuit. Refer to

→ Chapter ‚ÄûRefrigerant Circuit, Flushing (Cleaning) with

Refrigerant R134a“. |

|

| High and low pressure normal |

| A/C compressor noise (particularly after switch-on) |

| The required cooling performance is obtained |

|

|

|

Note

Note

| Overfilling with refrigerant oil can occur if, for example, the

compressor has been replaced without adjusting the quantity of

refrigerant oil. |

| If the A/C compressor is not replaced, the refrigerant oil should be

drained from the A/C compressor via the oil drain plug. Out of the

entire quantity of refrigerant oil, 50 grams should be put in the A/C

compressor and the rest in the refrigerant circuit. Refer to

vehicle-specific repair manual. |

–

Turn off the ignition.

–

Connect pressure gauge battery (A/C service station).

–

Take pr ...

Specified Values

Note

Connecting service station. Refer to

→ Chapter ‚ÄûConnecting Service Station‚ ...

Other materials:

Switching the front passenger front airbag on and off manually using the key-operated

switch

Fig. 58 In the stowage compartment on

the front passenger side: key switch for disabling and enabling the front airbag

on the front passenger side

First read and observe the introductory information

and safety warnings

The front passenger front airbag must be switched off when securing a

...

Introduction

This chapter contains information on the following subjects:

‚Üí Operating ParkPilot ‚Äâ

‚Üí Acoustic and optical ParkPilot signals at the rear of the vehicle

The ParkPilot assists the driver when manoeuvring and parking.

The ultrasound sensors in the rear bumper transmit and recei ...

A/C Refrigerant High Pressure Switch -F23

Note

For switching pressures, removing and installing switches

and switch arrangement and version, see vehicle-specific

refrigerant circuit.

Refer to

→ Rep. Gr.87.

...

© 2016-2025 Copyright www.vwpolo.net

Note

Note Note

Note Note

Note Note

Note Note

Note Note

Note Checking

Checking Checking with Expansion Valve, Receiver/Dryer and A/C Compressor Regulator

Valve -N280-, Externally Regulated A/C Compressor

Checking with Expansion Valve, Receiver/Dryer and A/C Compressor Regulator

Valve -N280-, Externally Regulated A/C Compressor