Volkswagen Polo Service & Repair Manual: Contacts in Contact Housing, Repairing

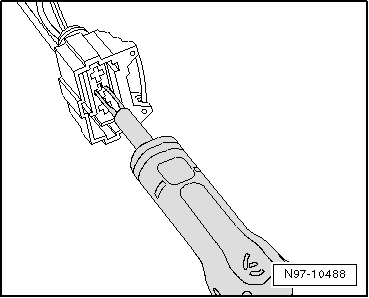

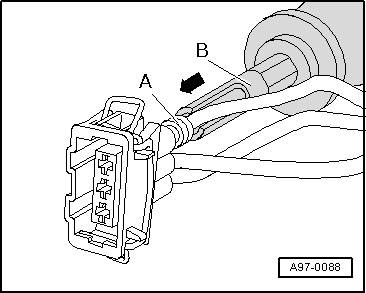

| First, open or release if necessary the secondary lock of

the contact housing. Refer to

→ Chapter „Contact Housings, Releasing and Disassembling“. |

|

|

|

| – |

Release contact (primary lock) using the appropriate release

tool. Refer to

→ Chapter „Contact Housings, Releasing and Disassembling“. |

| – |

Pull contact at single wire out of contact housing. |

| – |

Take the yellow repair wire with the correct contact out of

the Wiring Harness Repair Set -VAS1978-. |

| – |

Free up repair point of vehicle-specific wiring harness

(approximately 20 cm to both sides of repair point). |

| – |

If required, remove wiring harness wrapping using a folding

knife. |

|

|

|

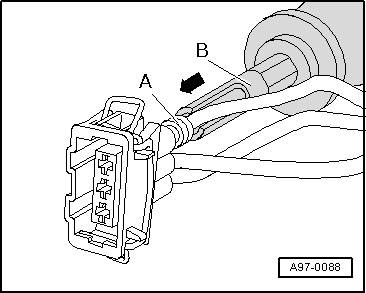

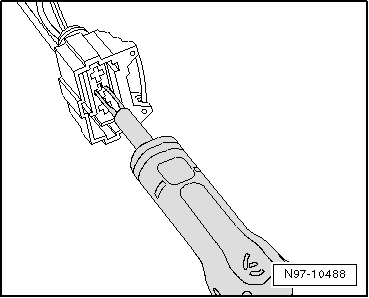

| – |

Insert new contact of repair wire into contact housing until

it engages. |

| – |

Slide a single wire seal onto the repair wire. |

Note Note

| When doing this, small diameter of single seal must point

toward contact housing. |

| – |

Slide single wire seal into contact housing using the

correct assembly tool. Refer to

→ Chapter „Single Wire Seals, Installing“. |

|

|

|

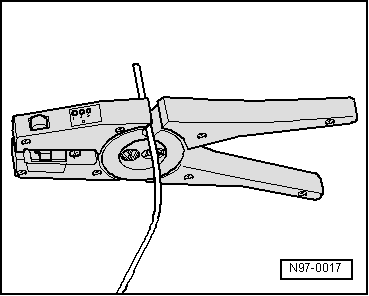

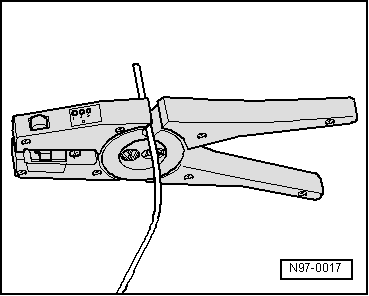

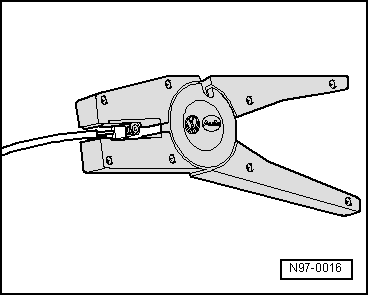

| – |

Shorten the repair wire and the vehicle-specific wiring

harness single wire as needed using the Wiring Harness Repair

Set - Wire Strippers -VAS1978/3-. |

|

|

|

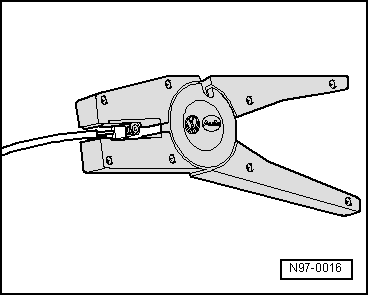

| – |

Strip ends of repair wire and of vehicle-specific single

wire using 6 - 7 mm wire stripper. |

| – |

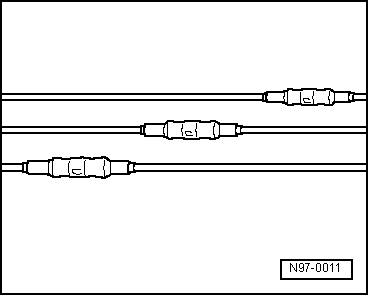

Crimp the stripped ends of repair wire and single wire of

vehicle-specific wiring harness using crimp pliers and a crimp

connection as described in chapter “Wire break with single

repair point”. Refer to

→ Chapter „Wire Break with Single Repair Point“. |

Note Note

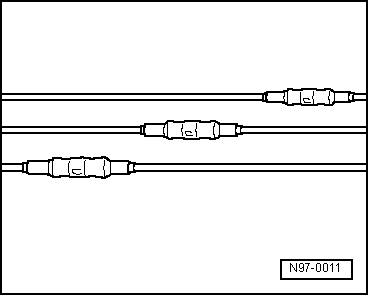

|

|

|

| Make sure that crimp connections do not lie directly next to

each other when several wires need to be repaired. Arrange the

crimp connectors at a slight offset so that the circumference of

the wiring harness does not become too large. |

| In the event the repair point was previous taped, this point

must be taped anew with yellow insulating tape after repairs. |

| Secure the repaired wiring harness if necessary with a cable

tie to prevent flapping noises while driving. |

|

|

|

Note

Observe general notes for repairs on the vehicle electrical

system. Refer to

→ Chapter „Vehicle Electrical System, General Repa ...

Note

Single wire seals prevent the penetration of water and dirt

into the contact housing. They are installed, for example, in

the engine compart ...

Other materials:

Indicator lamp in the vehicle key

Fig. 20 Indicator lamp in the vehicle

key

First read and observe the introductory information

and safety warnings

If a button on the vehicle key is pressed briefly, the indicator lamp (arrow)

flashes once. The lamp will flash several times if the button is pressed and held,

e.g. convenien ...

Discharge Refrigerant Circuit with A/C Service Station

Caution

If it is suspected that chemicals were added to the

refrigerant circuit to seal leaks, do not connect the

A/C service station and do not extract the refrigerant.

...

Aquaplus Design and Multi-Color Paintwork

In order to achieve error-free design and multi-colored

paint applications using Aquaplus solid, metallic, pearlescent

base paint, pay attention to the important notes and in some

cases use special tools.

Preparation:

...

© 2016-2026 Copyright www.vwpolo.net

Note

Note Note

Note Contact Housings and Connectors, Repair Information

Contact Housings and Connectors, Repair Information Single Wire Seals, Installing

Single Wire Seals, Installing